At ASD we offer a wide range of innovative value-added processing options that allows us to support all your requirements and customise solutions to fit your specific needs. This is one reason why we continually invest into know-how and processing technologies, so we can keep delivering sustainable, cost-efficient metal solutions and high-quality steel products.

What Differentiates Us

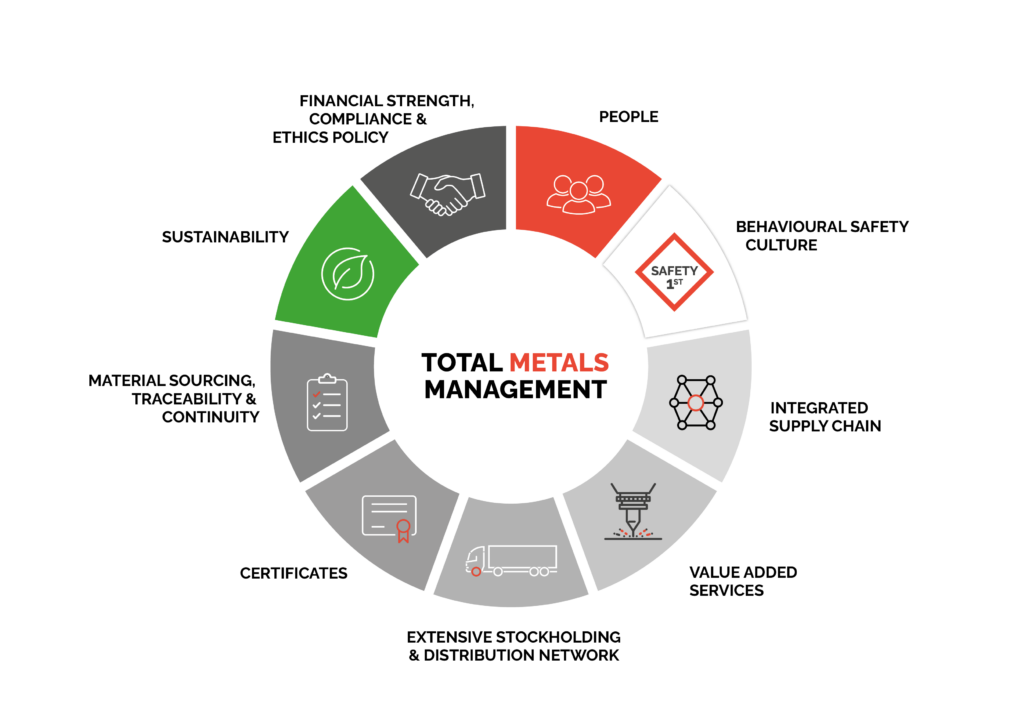

We developed Total Metals Management – one of our unique value propositions – to help you navigate the various supply chain challenges. If you need support with project management, we handpick a team of experts who will be on hand to ensure smooth execution from enquiry through to delivery.

Laurence Washbrook, Sales Manager at ASD: ‘At ASD we serve customers from diverse market sectors, from construction and motor vehicle manufacturing to oil and gas, nuclear and defence. We are unique in our offering and customers come to us because they know that we are equipped to provide them with the support they need. From help with design ideas, CAD drawings and sourcing of the material to working on projects that need completion within difficult deadlines, we are on hand to assist them. It doesn’t matter how large, small or complex their cutting requirements are, we will do our best to get them the products and services they need when they need them.’

3D Processing Solutions at ASD

You’re sure to find what you need with our comprehensive options for 3D processing:

TUBE LASER CUTTING

Our laser processing unit located in the heart of the Midlands is equipped with an impressive portfolio of state-of-the-art 3D laser cutting machines. We have also invested in a second Adige LT14 Jumbo laser, which has enabled us to further increase our capacity and provide a more advanced service to our customers.

Thanks to the expertise of our specialised CAD team, we offer complete in-house solutions no matter how large, small or complex your cutting requirements. Our capabilities include:

- Providing ready-to-assemble kits of parts

- Handling large volumes of project work with close tolerances and complex geometries

- Servicing contractual work and repetitive requirements

- Providing access to skills and expertise

- Offering flexible lead times

- Processing hollow sections, tubular products, beams, columns, split tees, angles and channels

- Dealing with parts up to 355mm in diameter and weights up to 100kg/m

- Laser cutting 20mm thick mild steel and weld prepping 16 mm thick mild steel material up to 45 degrees

- Measuring parts in 3D with our portable CMM 7-axis articulated scanning system and high-precision laser scanner.

LASER-ARRAY AUTOMATED INSPECTION

Our custom-made, automated inspection line for laser-cut components is a non-contact laser measurement system that allows us to ensure precise dimensions on critical components. The system offers measurement capabilities for length, cross-sectional dimensions, straightness, twist and cut features on sections up to 200m x 100m x 9m, providing our customers an increased level of quality assurance.

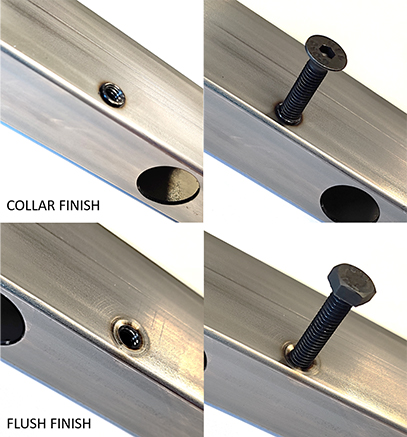

FLOWDRILLING

Flowdrill is a complementary service offered in relation to tube-lasered parts. By using high rotational speed and pressure, it creates holes in various materials. This is particularly useful when customers require a thread in thin materials without the need for thread inserts. The material is not removed but instead forms a sleeve around the hole, resulting in a sleeve length that is up to three times the original thickness. We can also offer a collar or plane surface finish with our Flowdrill technology.

To find out more about our processing capabilities, contact our team here

ASD’s Processing Capabilities: Delivering Comprehensive Profiling Solutions

ASD’s Processing Capabilities: Expert De-coiling, Slitting, and Blanking Solutions

ASD’s Processing Capabilities: Advanced Sawing, Drilling, Shot Blasting, and Painting

ASD’s Processing Capabilities: Adding Value with Section Bending, Routing, Punching & Shearing