Aluminium 3003 is a medium-strength alloy known for its substantial corrosion resistance. That and its other characteristics make it a popular choice of material across multiple industries. In this post, we explore Aluminium 3003’s unique properties and some of its common industrial uses. Read on to learn more.

Core Properties of Aluminium 3003

Aluminium 3003 boasts several key features that make it a preferred material in various sectors:

- Corrosion Resistance: It has excellent ability to withstand the effects of environmental elements without degrading.

- Strength: Aluminium 3003’s strength is adequate for moderate-demand applications.

- Thermal Conductivity: It is efficient in heat transfer, which is essential for applications like HVAC (heating, venting, and air-conditioning) systems.

- Weldability: It joins superbly with other metals, which is crucial for more complex manufacturing applications.

- Formability: It can easily be shaped into different forms, allowing for versatility in design and application.

Pivotal Applications by Industry

We’ve just listed the key properties of Aluminium 3003 that make it the material of choice across a number of industries including construction, HVAC systems, storage tanks, and more. Let’s take a look at some of the most common uses of this alloy in each industry.

Construction Industry

Aluminium 3003 is lightweight, strong, and resistant to corrosion, making it ideal for use in:

- Roofing and Rainscreens: It enhances building longevity by protecting against moisture and facilitating proper ventilation.

- Decorative Trimmings and Architectural Flashings: It offers an aesthetic finish while protecting corners and edges from water ingress.

- Façade Panels: It is used for aesthetic façades that require durability against environmental conditions.

Aluminium 3003 is versatile enough to meet the aesthetic and functional demands of modern architecture. The alloy’s formability makes it possible to create intricate designs for decorative trimmings and other architectural details.

Alongside its incredible versatility, Aluminium 3003 is known for its durability against harsh weather conditions, making it an excellent choice for gutters, downpipes, and window frames.

But its potential doesn’t end there. With its aesthetic appeal and low maintenance requirements, it is also a popular choice for interior applications such as ceiling panels and decorative trims. And Aluminium 3003’s compatibility with various fabrication techniques makes it a top choice for construction projects that seek both longevity and design flexibility.

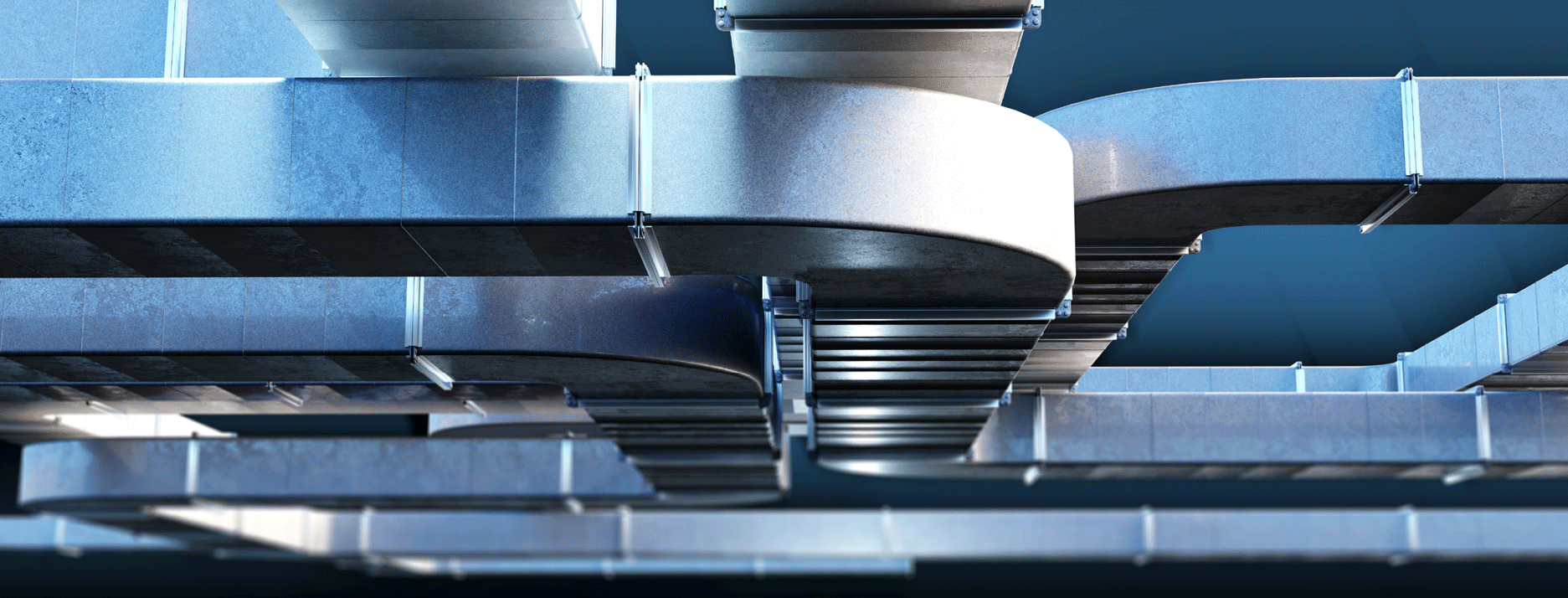

HVAC Systems

Aluminium 3003 is a popular choice for the HVAC industry owing to its lightweight nature and excellent formability, which simplify installation processes and reduce structural strain. It is commonly used in:

- Ductwork: Its light weight reduces the load on supporting structures and simplifies installation.

- Heat Exchangers, Air Handling Units, and Condenser Coils: Its excellent thermal conductivity ensures efficient heat transfer, which is crucial for optimal HVAC performance.

Aluminium 3003 is an excellent choice for HVAC systems because it is corrosion resistant, which makes it durable in various environmental conditions, both indoors and outdoors.

Additionally, it can be processed using welding and other fabrication techniques to meet the specific requirements of any HVAC system, ensuring optimal performance and longevity.

Storage Tanks

Aluminium 3003 is particularly effective in environments where resistance to corrosion from chemicals is crucial. Because it ensures long-term reliability even in demanding environments, it is commonly used in the making of tanks that store water, fuels, and acids.

Aluminium 3003 is incredibly formable, too, which allows fabricating storage tanks with complex shapes and configurations to efficiently accommodate specific storage needs. Additionally, it is light in weight, which means it is easier to transport, install, and maintain, reducing overall project costs.

Chemical Equipment

Aluminium 3003 is a chemical industry go-to material for crafting durable equipment such as vessels and piping. Known for its excellent resistance to corrosion from acids and alkalis, it helps ensure that equipment lasts longer and remains leak-free, safeguarding against contamination.

What’s more, Aluminium 3003 is highly malleable, making it ideal for creating complex shapes needed for customised chemical-processing set-ups.

This combination of durability and flexibility makes it an essential material in the sector, protecting both processes and products.

Value-Added Services

At ASD, we stock Aluminium 3003 in 1.5mm, 2mm and 3mm coils of varying widths. We also offer several complementary value-added services to accommodate specific project requirements, including:

- De-coiling to length

- Slitting

- Flat laser cutting

- Pressing (press brake)

- Powder coating

- Printing part numbers

If you want more information on Aluminium 3003 and the value-added services we offer at ASD, please get in touch with our team here.