As we begin the new year, we caught up with Helen Shaw, Director of Sales at ASD, and asked her to tell us about the recent advancements and the strategic focus for the year ahead. In this short interview, Helen reveals how ASD is shaping the steel industry to meet evolving customer needs in the year ahead, by expanding capabilities and investing in state-of-the-art machinery.

Q: Helen, can you start by sharing the strategic focus of ASD and how 2024 has been a pivotal year for the company?

Helen: As you said, 2024 has been truly transformative for ASD, and much of the credit goes to our new owners, Hierros Añón, the largest family-owned metal distribution business in Europe. What truly sets them apart is not just their scale but their genuine passion for the industry and their unwavering commitment to being the best at what they do. Their focus on serving local customers with excellence and delivering customers real value through continual investment in inventory and automation aligns perfectly with our goals at ASD.

This shared ambition has provided a springboard for growth. Hierros Añón’s confidence in our potential has empowered them to invest boldly and strategically, with the clear objective of making ASD the UK’s largest stockholding and processing supplier. Their enthusiasm for innovation and growth is deeply inspiring and has energised our entire team.

At ASD, our strategy is centred on growth – expanding our capabilities, ultimately, to better serve our customers. In 2024 we achieved several significant milestones that underscore this focus. For instance, we opened our Newbridge site in Edinburgh, which is now the largest metal stockholding and processing warehouse in Scotland. We also acquired the assets of Atlantic Steel in Birkenhead, a move that has strengthened our market position for de-coiled hot rolled sheets and reversing mill plate offerings. Additionally, we invested £5.5 million in a state-of-the-art automation line in Leeds, designed to address customer pain points and enhance efficiency.

Looking ahead to 2025, we have even bigger plans. We’re increasing inventory across all sites – currently standing at over 70,000 tonnes – to ensure that we’re always ready to meet customer demand locally and nationwide. We’re also continuing to invest in cutting-edge technology to streamline our processes, reduce lead times, and maintain the high standards our customers expect.

Q: Can you elaborate on how the new automation line enhances ASD’s capabilities and how it supports your customers?

Helen: The automation line we introduced at the end of 2024 is a transformative step forward for both ASD and our customers. It’s particularly impactful for the construction sector, which includes industries such as commercial and residential buildings, education and leisure projects, hotels and sports stadia, medical facilities, rail, and infrastructure projects.

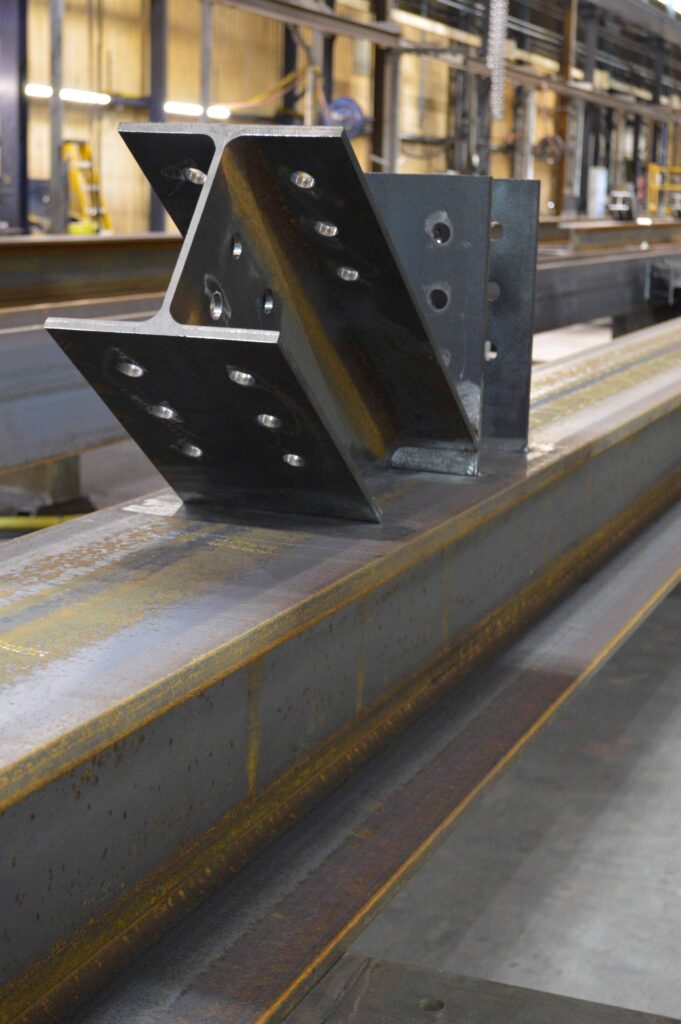

This advanced capability enables us to deliver fully fabricated components, saving our customers who work on construction projects valuable time and resources. For instance, tasks like marking, traditionally performed manually, are now automated – eliminating errors and significantly accelerating processes. These investments not only help our customers overcome challenges such as labour shortages and production bottlenecks but also provide them with more accurate and high-quality output, which gives them a competitive edge in meeting project timelines.

What is also exciting is the new automation line’s ability to handle a wide range of complex tasks, such as notches, bolt holes, flange mitres, bevels, weld preparation and producing kits of parts. And it perfectly complements ASD’s Westok steelwork fabrication offering. ASD Westok is a specialist in EXC4 steelwork fabrication, and throughout the years it has built a strong reputation for manufacturing ribbon-cut cell beams, plate and box girders, and cellular UBs. In the most recent years, their expertise has also expanded to include fabrication of volumetric units for the modular sector, highway and transfer beams, trusses, and heavy industrial steelwork using S355, S460, and weathering steel.

This comprehensive offering makes ASD the only steel supplier in the UK capable of sourcing materials, designing and value-engineering them, processing them, and fabricating them to UKCA/CE EXC4 standards. “

Q: Speaking of construction, how is ASD addressing the broader challenges faced by customers in the industry?

Helen: The construction industry is undergoing a transformative period, but it’s not without its challenges. In the last five years, the industry has lost over 300,000 workers and continues to lose older, self-employed construction workers, leading to labour shortages. Additional issues like fluctuating demand and the increasing need for sustainable practices are reshaping how projects are delivered.

As already mentioned, at ASD we’re tackling these issues head-on by leveraging innovation and strategic investments. For instance, our ability to supply fully fabricated parts eliminates the time- and labour-intensive manual processes that can slow down projects. By automating traditionally manual tasks, we’re allowing our customers to focus on their core operations.

Q: You mentioned sustainable practices; how exactly can ASD support construction customers?

Helen: When it comes to sustainable practices, I believe that we are again uniquely positioned to contribute towards more sustainable construction process:

- Our ability to collaborate with our own group mills enables us to produce material to exact sizes, helping customers eliminate waste and reduce emissions.

- We’re able to source greener and more innovative materials, too.

- We have expertise in the production of modular/volumetric units, hybrid construction techniques, and steel reuse projects.

- We can offer lightweight, low-carbon, value-engineered design solutions as well as TMM (Total Metals Management) – ensuring that complex and demanding industry projects that require first-class service and high-quality metals purchased on a project-by-project basis are handled by a dedicated team of experts, adhering to strict timelines and safety standards.

Q: Finally, what excites you most about ASD’s future?

Helen: What excites me most is the opportunity to drive real innovation in an industry that’s constantly evolving. At ASD, we’re not just responding to change – we’re driving it. Our investments in technology, our expansion efforts, and our focus on solving customer challenges are all part of a larger vision to redefine what it means to be a metal and processing supplier. The future is incredibly bright, and I’m proud to be part of a team that’s shaping it.