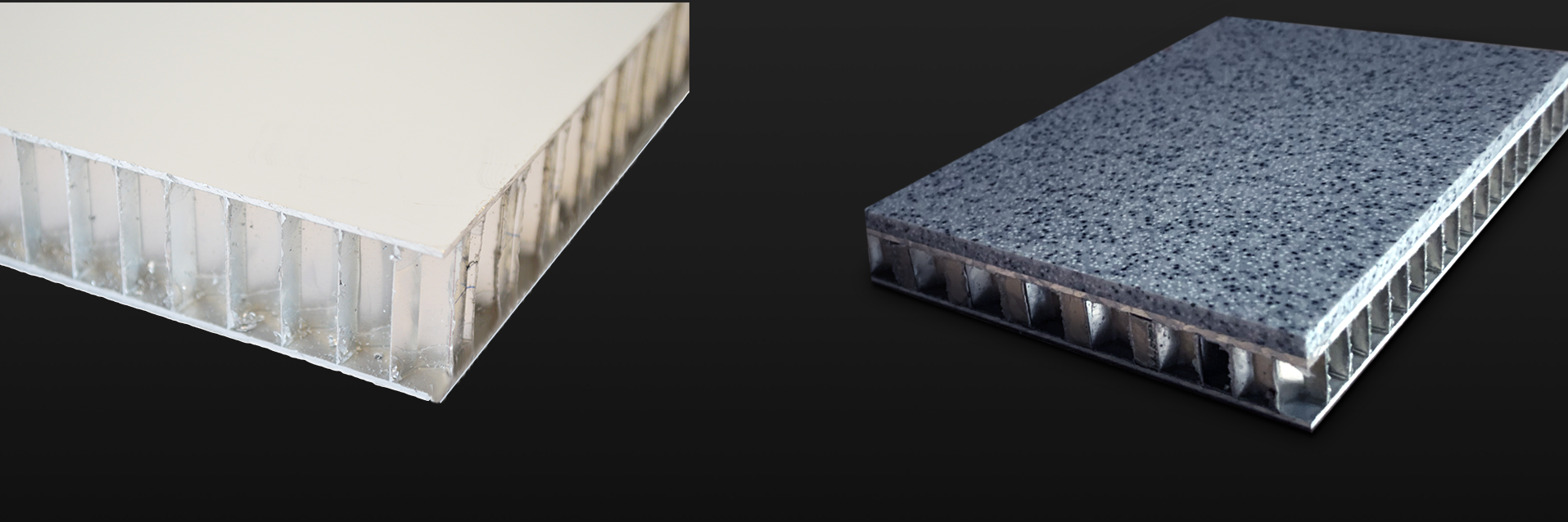

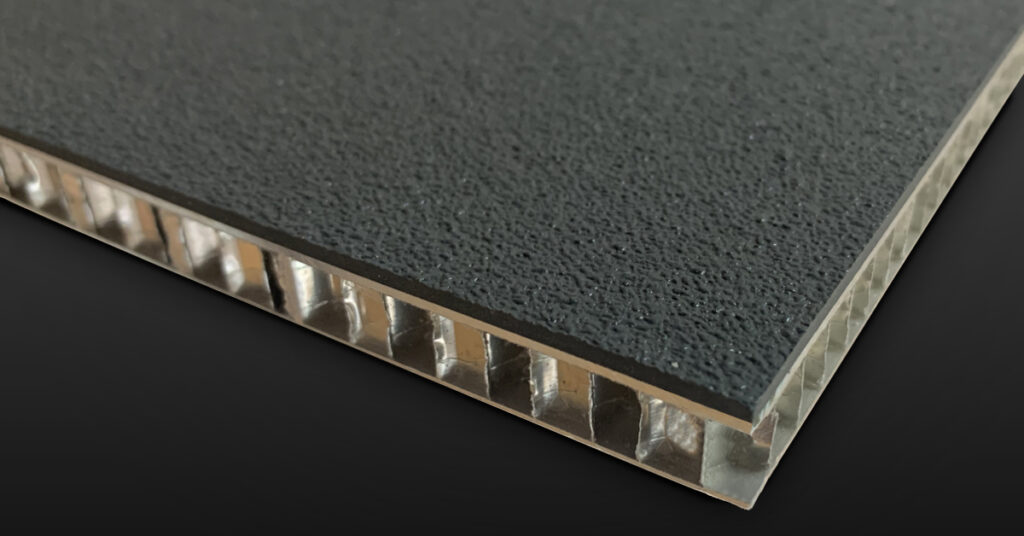

ALUCORE® is an innovative aluminium-based composite panel renowned for its unique structure, high durability, and versatility across multiple sectors. Designed with a sandwich-style panel configuration, ALUCORE® is lightweight yet highly rigid, providing a superior alternative to traditional honeycomb composite panels. Its unique combination of an aluminium core and aluminium cover sheets, bonded in a continuous process, makes it a valuable material in architecture, transport, industrial production, and more.

What Is ALUCORE®?

ALUCORE® is an advanced aluminium sandwich panel that stands out due to its core and cover sheets, which are bonded through a seamless, continuous process. Unlike conventional honeycomb composite materials, this bonding method results in exceptional product quality, durability, and resilience, making it ideal for demanding applications. Its structure provides remarkable peel strength and a tough yet flexible surface that can withstand various environmental factors without becoming brittle. These characteristics allow it to perform well in settings requiring a balance of rigidity and weight efficiency.

Unique Properties of ALUCORE®

ALUCORE®’s construction process and material composition lend it several key benefits, including:

- Superior Quality and Surface Evenness: The continuous bonding process ensures a smooth surface and reduces any irregularities in the panel, enhancing the aesthetic appeal in architectural applications.

- Exceptional Peel Strength and Formability: Unlike many composite panels that tend to be brittle, ALUCORE® exhibits strong adhesion and toughness, allowing it to be formed and customised easily.

- Lightweight with High Rigidity: ALUCORE® maintains high tensile strength despite its low weight, making it a practical choice for applications where weight reduction is crucial.

These properties collectively make ALUCORE® an attractive option in industries prioritising durability, formability, and economic efficiency.

Applications of ALUCORE® across Various Sectors

ALUCORE®’s unique composition has made it a popular material choice across diverse fields:

- Shipbuilding

In the shipbuilding industry, ALUCORE®’s light weight and durability are essential for meeting fire protection standards and achieving weight reduction goals. Its use is prevalent in ship interiors for ceilings, walls, and furniture, as well as in balcony partitioning. This composite panel provides not only structural integrity but also economic efficiency, helping to reduce overall ship weight without compromising strength.

- Interior Construction

ALUCORE® is ideal for applications requiring modular and adaptable construction. It’s commonly used in:

- cleanrooms, partitions, lightweight containers, and cabins for machine tools and wind tunnels

- curtain walls for stairways and public areas, with the potential for HPL (high-pressure laminate), veneer, and foil finishing options.

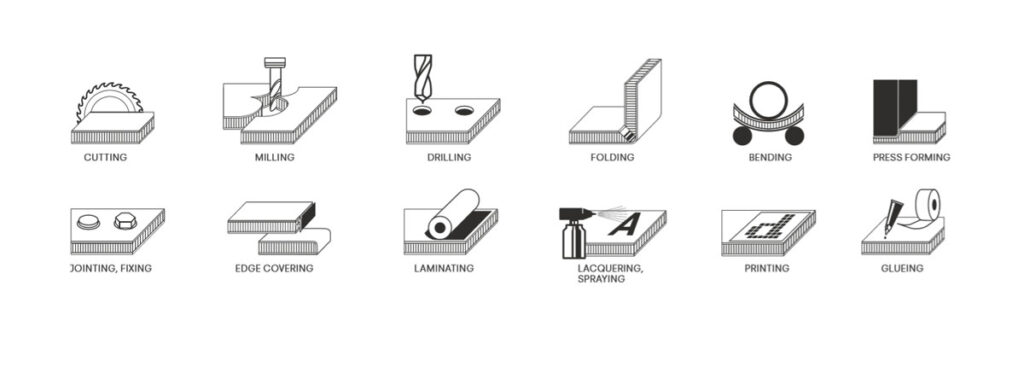

Its compatibility with standard construction tools allows for flexible, on-site modifications, making it convenient for builders who need versatile materials.

- Architecture

ALUCORE® offers architects a material that pairs well with technical and aesthetic requirements for façade cladding and roofing. Its rigidity and lightweight design allow it to handle large self-supporting roofs or façades that face high wind loads. The panel’s consistent surface, coupled with mounting systems, provides a flawless finish, making it ideal for creating visually appealing and structurally sound designs.

- Rail and Transport Vehicle Construction

ALUCORE® aligns with strict environmental standards by offering lightweight, sustainable material options. Its low weight helps reduce CO2 emissions and eases strain on road and rail infrastructure. ALUCORE® panels are fully recyclable, further contributing to sustainable construction practices. Applications in this sector include interior cladding, wall cladding, roofing for rail vehicles, lorry superstructures, cabins, and doors.

Sustainability and Environmental Benefits of ALUCORE®

- During the life cycle of Alucore panels, no substances containing CFC are released into the environment.

- ALUCORE® can be fully recycled with any other aluminium without prior separation or sorting (scrap value).

- Due to its lightweight nature, it can help significantly reduce CO2

ALUCORE® Processing

If you’d like to learn more about ALUCORE® and its application in specific conditions, we invite you to get in touch with our team here.