The modular construction industry is evolving to keep up with the growing demand for modern methods of construction. One of the approaches is Seismic demonstrator, a platform-based construction solutions. It has been designed to specifically help the industry reach the government’s Construction 2025 targets. This system is based on a standardised steel frame and a set of components that build and configure a variety of building types. ASD is part of the supply chain for the Seismic I and Seismic II models.

ASD’s Ability to Offer Kits of Parts for Modular Building Frames

Being part of the official supply chain for the Seismic I and Seismic II models, ASD is able to supply kits of parts for modular building frames. We can offer clients use of our extensive laser-cutting facilities – both tube and flatbed laser – allowing tight tolerances to be met. We have also invested into two Ficep CNC-cutting machines: Endeavour – a section processing machine and Gemini – a plate processing machine. These enable us to cut beams and columns and produce plate fittings to provide kits of parts. Furthermore, we can offer our clients additional cutting and drilling services on cambered asymmetric beams supported by thermally cut fittings with tight tolerances.

To serve the modular industry better, we have also established a modular processing cell in Dudley, Midlands. At this facility we are able to offer extensive tube and flat laser processing capabilities, an automated inspection line and bespoke kitting. It has been specifically designed to process high-volume production of products with close tolerances and complex geometries.

ASD’s Expertise in Laser Cutting

ASD is equipped to support businesses with varying modular build requirements thanks to the scope and scale of our tube laser technology. This, coupled with our dedicated modular processing cell, brings together our knowledge and expertise and allows us to offer the sector unrivalled support.

ASD has invested in two LT14 tube lasers and seven smaller tube lasers to serve the industry better. The LT14 Jumbo lasers are capable of processing parts up to 355 mm in diameter and weight up to 100 kg/m. They can also process hollow section tubes, beams, columns, split tees, angles and channels. Each laser has a 4.5 KW Rofin CO₂ laser source with the ability to laser cut 20 mm-thick mild steel and weld prep 16 mm-thick mild steel material up to 45 degrees. These capabilities make the LT14 lasers suitable for processing the requirements of the modular industry.

Our flat laser portfolio includes fibre and CO₂ laser cutting technology for processing various materials, including Carbon, Stainless, Galvanised Steel, Aluminium, and Cor-ten® steel. Our machines can handle materials up to 6000mm in length and 2000mm in width. We also provide UKCA/CE marking to execution class 4 standards.

Our CAD team utilise the latest versions of Solidworks and Artube 3 CAD software, which is capable of importing full 3D models/assemblies including IFC files (Tekla), STEP, IGES and X_T. Our team of in-house experts have a combined total of 30 years’ experience in tube laser cutting and will be happy to liaise with customers if parts cannot be produced in order to find a solution to fit the customer’s requirements.

Catering to the Specific Needs of the Modular Build Industry

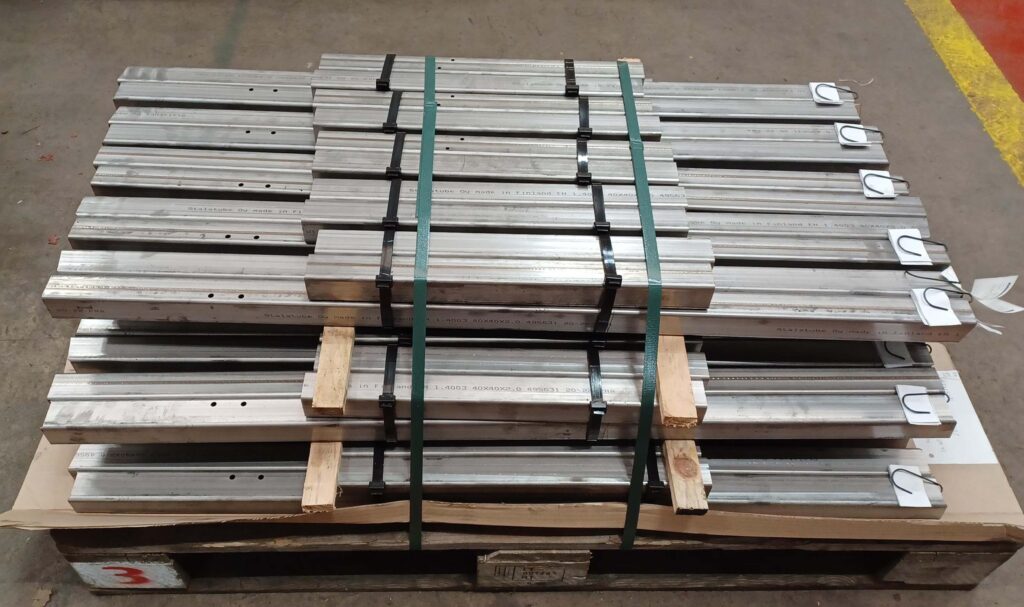

ASD supplies parts in kit form so that they can be easily configured to suit the specific requirements of each client. These products can also feature directional etching, wall numbers and additional markings for easy identification on site.

In addition to components for floor, wall, ceiling and roof modular structures, we also supply:

- Machined shim plates

- Hot Dipped Galvanised slit coil for rolled sections

Our Experience with Modular Projects

ASD’s team is highly experienced and offers complete project management support to help customers develop and implement the best solutions for their modular projects. Regardless of the size of the requirement, from bespoke and standard material procurement to supplying kits of parts or delivering fully fabricated steel frames, we have the necessary expertise and capabilities to ensure the successful delivery of your projects.

Get in touch with our team for further information and to discuss your specific requirements.

Related articles:

Modular Construction: Delivering Excellence to the Modular Sector

Modular Construction: ASD Westok – Delivering Fully Fabricated Volumetric Frames for Modular Sector

Modular Construction: ASD’s Organically Coated Steel Tailored to Modular Needs