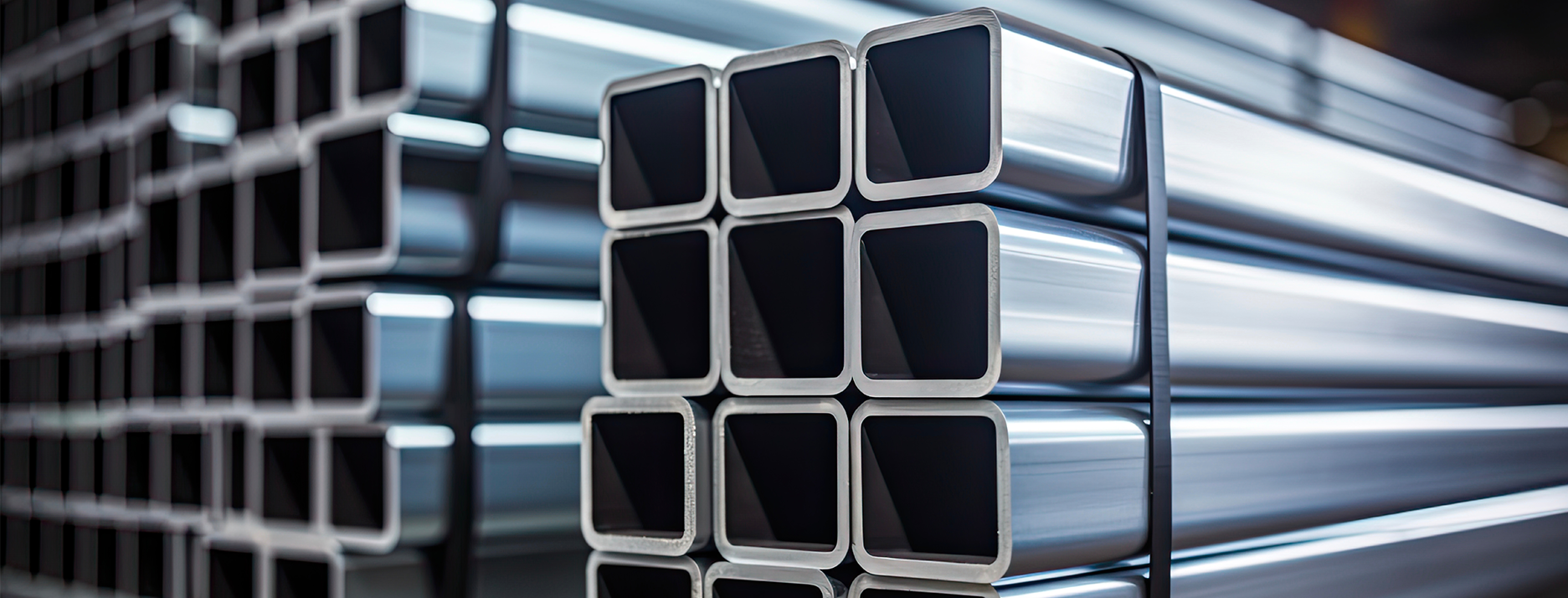

Electric Resistance Welded (ERW) tubes offer a myriad of advantages and are a versatile and efficient tubular solution that is adaptable to a wide array of applications. Also known as precision or mechanical tubes, they find utility in numerous mechanical contexts due to their malleability and formability, enabling bending or compression without compromising structural integrity.

At ASD, we stock a diverse range of shapes in ERW (Electric Resistance Welded) tubes, offering wall thicknesses from 0.9mm to 5.0mm and diameters ranging from 12mm to 65mm. These precision tubes are engineered to meet exacting standards, making them ideal for various industrial applications.

Moreover, in addition to our standard products, we have the capability to source customised tubes tailored to our customers’ specific needs. This flexibility is made possible through our Hierros Añon group offering, which includes several tubular mills specialising in the production of a wide variety of carbon and stainless tubes, as well as precision tubes range. With this robust production capacity and customisation options, we can cater to diverse industrial requirements, ensuring both high quality standard and reliability.

The advantages and benefits of our ERW tubes include the following:

- Enhanced dimension accuracy compared to seamless pipes attributed to precise strip rolling

- Impressive impact toughness

- Strong corrosion resistance in pregalvanised ERW pipes

- Uniform microstructure

- Consistent thickness

- Smooth surface finish

- Easily coated (zinc, chrome, powder)

Characterised as round, rectangular, square, flat-sided oval (FSO) per EN 10305:2010 Part 3 and 5 E220, as well as sculptured, ERW tubes can be used across a variety of industries:

FURNITURE

ERW tubes play a significant role in furniture production. The integration of steel with other materials grants remarkable flexibility, facilitating the creation of distinctive designs. ERW tube components are harnessed in the crafting of a diverse array of items, including:

- Street furniture: The term is generally used to encompass road signage, gantries and lighting standards as well as benches, shelters, bike stands, and balustrades, showcasing the adaptability of ERW tubes in outdoor urban spaces.

- Seating furniture: Steel finds its place in various seating solutions, catering to office, educational, medical and stadium environments. From office chairs to medical/hospital beds and bedside tables, steel components contribute to sturdy and functional designs.

- Display and shop fittings: The versatility of ERW tubes extends to display and shop fittings, where they form the backbone of structures that showcase products and merchandise.

TRANSPORT

The remarkable durability of ERW tubes also makes them widely used in the transport sector. Their applications include:

- Handrails and seat frames for public transport vehicles: ERW tubes are instrumental in crafting handrails and seat frames for buses and trains, ensuring safety and stability for passengers.

- Automotive and commercial vehicles: Within the realm of automotive and commercial vehicles, ERW tubes are used in the manufacture of truck bodies, heavy vehicle axles, heavy vehicle exhausts, car seats, car exhaust systems, steering columns, car axles, rear wheel drive prop shafts, fuel filler pipes, door intrusion beams, rollover protection, oil dip stick pipes, airbag systems, exhaust pipes, ride and motion control devices, and much more, contributing to the structural integrity and performance of these vehicles.

AGRICULTURE

To fulfil the structural demands of the sector, agriculture has a broad spectrum of applications for ERW tubes. The most common uses include:

- Greenhouses, nurseries, hay shelters, and construction of roofs, pens and cattle control systems, feeding troughs and frames: ERW tubes are an ideal solution when there is a need for resilient, lightweight and cost-effective structures.

- Agricultural vehicles and implements: ERW tubes are used to craft rollover protection, drive shafts, couplings, hitches, structures, exhaust systems, etc.

CONSTRUCTION & INFRASTRUCTURE

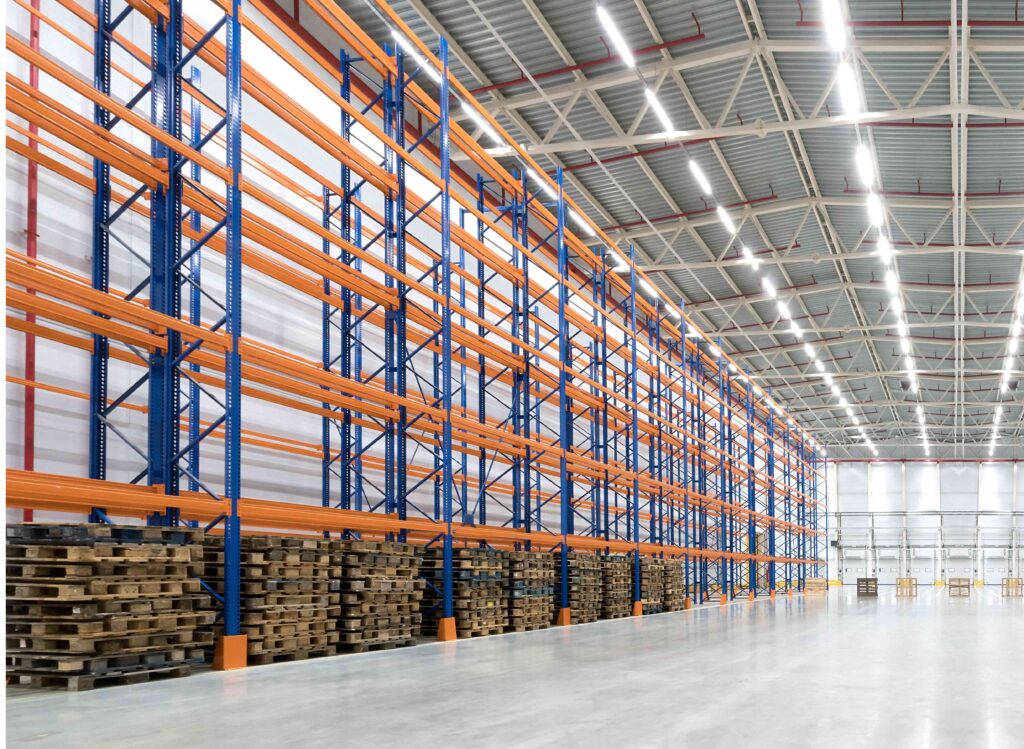

ERW tubes are a popular choice for contemporary architecture due to their economical nature, durability, versatility and recyclability. These tubes have extensive applications across construction and infrastructure, contributing to a diverse array of items.

- Scaffolding, railings, fencing, temporary fencing: ERW tubes serve as key components in the creation of scaffolding, railings, and fencing, ensuring structural integrity and safety.

- Signage: The versatility of ERW tubes is harnessed in crafting impactful signage structures, enhancing visibility and communication.

- Warehouse shelving, racking, and storage solutions: ERW’s strength and reliability make it a prime choice for crafting storage and racking systems, ensuring organised spaces for various goods and materials.

OTHER

ERW tubes find additional applications in the fabrication of machine parts, conveyor belts, sports equipment and heavy industrial equipment. From furniture to construction and industrial equipment, ERW tubes stand as a versatile and cost-effective choice, contributing to sturdy and efficient solutions across industries.

PROCESSING ERW TUBES

At ASD we also offer a range of supplementary services tailored to ERW tubing. Our offerings include fast & efficient tube laser cutting, sawing, bending, rolling, flowdrilling and countersinking. Speak to our experts today to see how we can support your requirements.

If you are interested in this product reach out to our team for a quote.