The UK construction sector continues to struggle with an ongoing lack of innovation, and despite advancements in technology and materials, the industry remains relatively slow to adopt new practices and continues to be heavily reliant on traditional methods.

The need to embrace carbon-friendly design solutions in the construction sector is now widely understood. The built environment is a significant contributor to global carbon emissions, and the lightweight low-carbon benefits of Westok’s ribbon-cut beam have been exploited for many years in new-build projects, and in more recent times, Westok beams have been utilised in award-winning city centre refurbishment/extension projects.

Images courtesy of McGee.

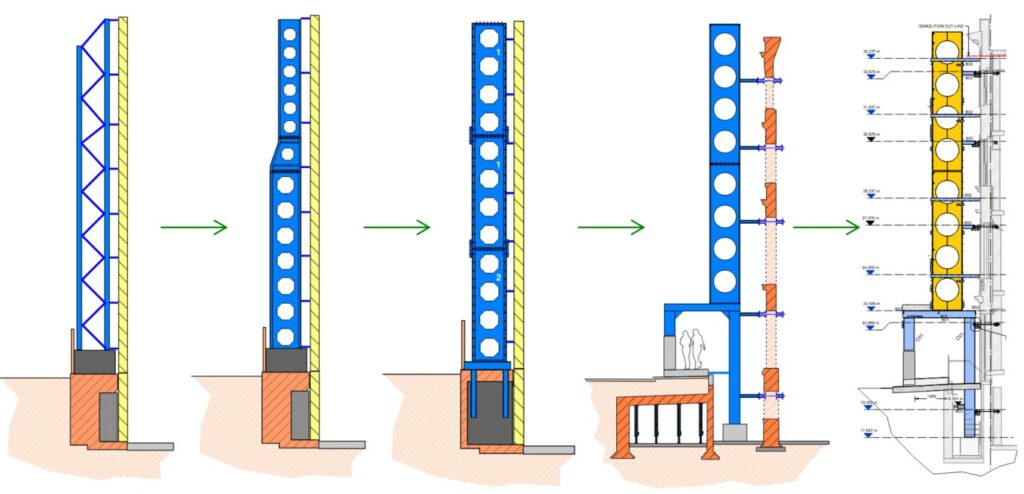

McGee has pushed the boundaries even further with the advancement of an innovative and carbon-friendly modular temporary works/façade retention solution currently in use at London’s largest mixed-use development in Mayfair and a large prime residential development in St John’s Wood.

Urban Façade Retention Solution Using Westok Cellbeams From Reused Steel – A World First!

Westok collaborated closely with McGee’s engineers to design a unique façade retention solution using expanded Westok ribbon-cut cellular beams, formed using reused 838UB sections supplied by EMR.

McGee’s innovation features patented Westok ribbon cutting of reused steel sections to replace the traditional system of trussed frames. The iterative process between Westok and McGee engineers developed the optimal cell diameter, spacing, and beam depth to meet the target strength and stiffness requirements to the modular system. Furthermore, the design developed optimal module lengths, minimising production waste for available reused sections.

Following a successful trial by Westok of defabricating an 838UB, the feasibility of safely removing RSA ledger angles and various other attachments on the reused sections was confirmed. Westok continued its work by manufacturing, processing, and fabricating 1300mm deep cellular beams. The net result is a fully modular system that can be demounted and used on multiple façade retention projects.

This project showcases the benefits of sustainable construction practices and the innovative use of reclaimed materials, setting a precedent for future developments. The project utilised UB 838x292x226 sections, but the same Westok process can be applied to any rolled section from reused stock. This is an important aspect of the benefits of Westok’s cellular beam, as there may be significant variability in the reused sections available at any point in time.

Given the innovative nature of the solution by McGee, Westok, and EMR, it is little surprise that the concept has been shortlisted for two awards at the British Construction Industry Awards: Net Zero Carbon Initiative and the Temporary Works Initiative of the Year. So watch this space!

For more information on sustainable construction solutions, speak to our Westok team.