There are many grades of Stainless Steel, each with unique properties suited for different applications: The most commonly used are Austenitic grades – 304/304L and 316/316L, which we covered in the previous article.

However, at ASD, we also keep a range of more specialised grades such as 4003 (also known as 1.4003), which is a Ferritic grade, the less common 321 grade, as well as Duplex Stainless Steel.

Additional Stainless Steel Types

Grade 321 Stainless Steel is primarily used for applications involving sustained exposure to high temperatures and/or corrosive elements. It is very similar to 304/304L Stainless Steel but with improved thermal strength. Common uses include:

- Chemical and Petrochemical, where it is used for processing equipment that must resist heat and corrosion.

- Power Generation, especially in nuclear and thermal plants for high-temperature components.

- Pharmaceutical and Biotechnology, in heated vessels and reactors where corrosion resistance is critical.

At ASD, we stock the 321 range in cold-rolled, hot-rolled, and quarto flat products.

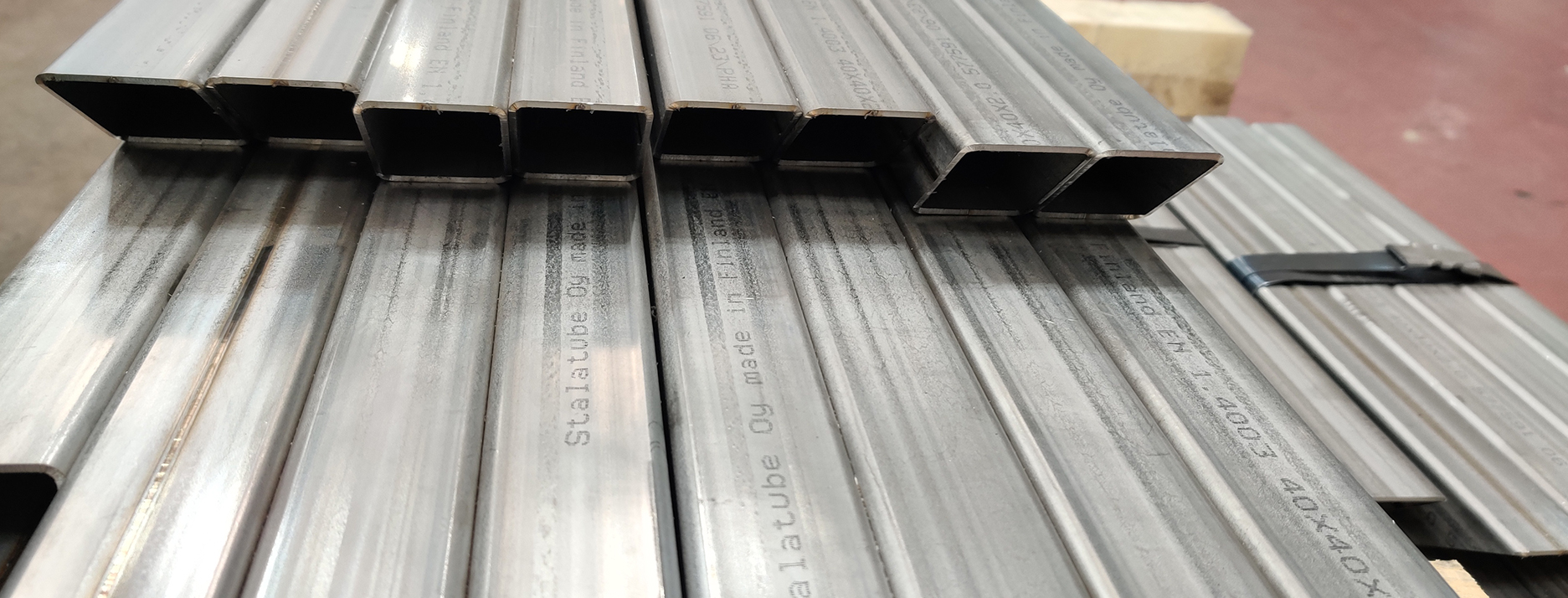

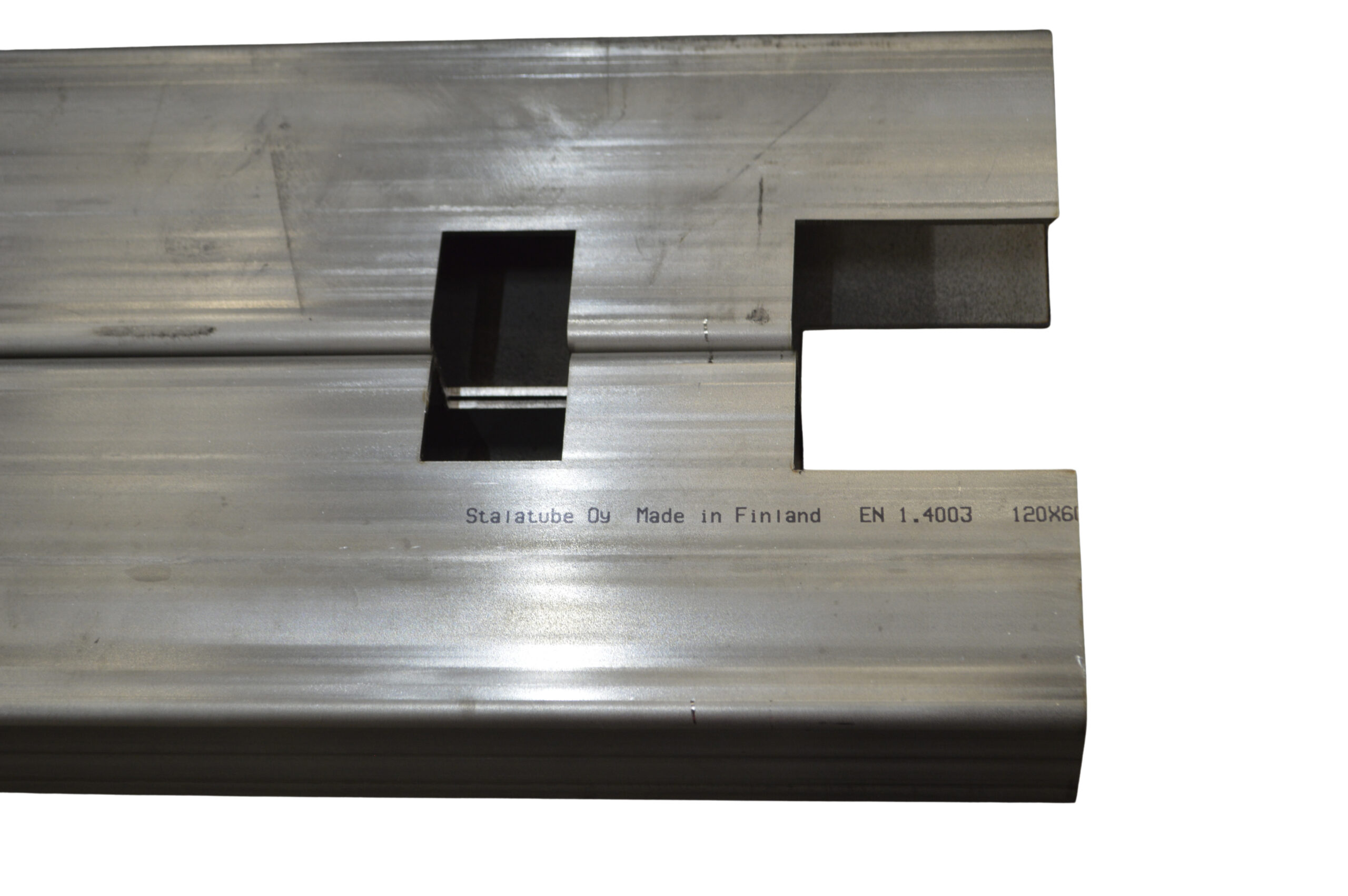

Grade 4003 Stainless Steel is a low-cost Stainless Steel designed as a cost-effective substitute for galvanised carbon steel. It is known for its good corrosion resistance compared to carbon steel, high strength, and excellent weldability and has good stress corrosion cracking resistance. Common uses include:

- Transport, such as railway rolling stock and shipping containers.

- Agriculture, in the manufacture of equipment for fertiliser plants.

- Mining and Quarrying, where it is used in structural components that are exposed to abrasion and light corrosion.

- Telecom / Data Infrastructure, in external cabinets, where painting is also carried out for added protection.

- Municipal and Public Works, where it is chosen for wastewater treatment plants, road furniture and barriers as it extends the life of components in harsh environments.

At ASD, we supply selected flat and tubular products in 4003 grade.

Duplex Stainless Steel

Duplex Stainless Steel combines features of both Austenitic and Ferritic steels. This makes it highly resistant to stress corrosion and offers great strength. It also has long-term durability to corrosive or harsh conditions, making it perfect for demanding environments such as marine, desalination plants, and offshore oil & gas platforms.

Applications of Duplex Stainless Steel Across Sectors

Duplex Stainless Steel is in high demand, especially where the durability and resilience of materials are paramount. Typical applications include:

- Oil & Gas – flanges, valves, tubes, and pipes

- Chemical processing – storage tanks

- Structural components in bridges

- Storage tanks and vessels

- Heat exchangers

- Process tanks in the Paper industry

Duplex’s exceptional strength and outstanding corrosion resistance make it a reliable and efficient choice for demanding environments. Its aesthetic appeal, high mechanical performance, and long life expectancy with low maintenance have also contributed to its growing popularity across various sectors. Duplex Stainless Steel is also extremely sustainable and 100% recyclable.

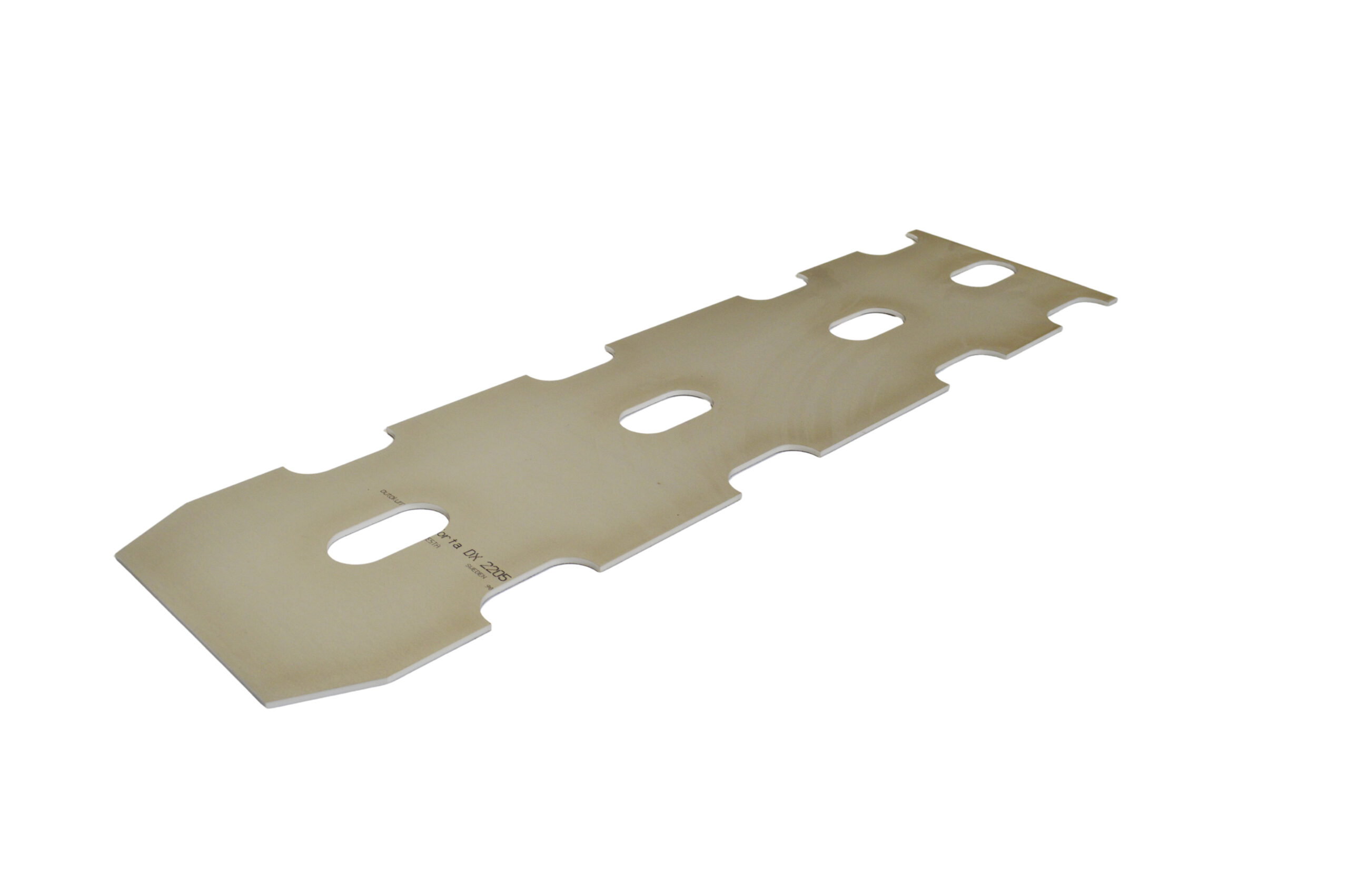

At ASD, we partner with Outokumpu and supply a range of Duplex flat products:

- 2205 – normally used for chemical tankers and bridge structural components. The product meets Norsok standards.

- 2507 – usually utilised in storage tanks and household heaters. The product meets Norsok standards.

- LDX2101 – typically used for deep-sea pipelines and desalination plants.

Stainless Steel Processing

A wide range of in-house value-added services, such as water jet cutting, tube and flat laser cutting, bending, and forming complements our extensive range of Stainless Steel products.

We have Stainless Steel designated machines to prevent the cross-contamination of materials. Moreover, our Dudley site features a dedicated Stainless Steel processing cell – a controlled ‘stainless only’ environment, where water jet, flat-bed laser, and press brake activities are conducted under conditions that prevent cross-contamination and foreign-object debris, with an emphasis on nuclear safety and quality awareness.

Want to find the right Stainless Steel for your application?

For additional information on the different Stainless Steel types or to get a quote for your next project, please get in touch with our team. Make sure also to check out our previous article, which explored Grade 304/304L and Grade 316/316L Stainless Steel and their applications. Additionally, look out for our next article about the different types of polished Stainless Steel finishes and how they are used.

Related articles: