Why Flexibility and Cut-to-Size Steel Supply Matter More Than Ever

The manufacturing and infrastructure world is moving faster than ever, and a one-size-fits-all steel supply is no longer enough. Projects are becoming more complex, lead times are tighter, and specifications are more exacting, creating a growing demand for flexibility and tailor-made solutions.

From energy and manufacturing to shipbuilding and construction, industries are under pressure to build stronger, safer, and more sustainable structures while keeping costs and timelines under control.

This guide looks at how a custom-made approach to hot-rolled steel can help remove unnecessary delays, reduce waste, and give projects an edge.

Why Steel Supply Still Causes Delays

In today’s industrial landscape, timing and precision can make or break a project. Yet, for many procurement and project teams, sourcing steel still means compromising on size, grade, or lead time.

The reality is that when it comes to hot rolled steel sheet, many suppliers out there still rely on fixed grades and standard sheet sizes. That puts the pressure back on project teams to work around what’s available instead of getting what they actually need. It means more cutting, more handling, and more coordination than should be necessary. In the end, it adds complexity, waste, and time to jobs that could be far more streamlined.

The Hidden Costs of ‘Close Enough’ Hot-Rolled Plates

Relying on standard hot-rolled stock might seem like the faster option at first. But once you start cutting down sheets, dealing with offcuts, or reworking parts that don’t quite fit, those shortcuts turn expensive.

The hidden costs quickly add up:

- extra material waste

- more handling and machining

- longer production timelines

- storage issues

- project delays.

Cut-to-size hot-rolled supply removes those headaches, especially on larger or more complex projects.

Why Suppliers’ Flexibility Makes All the Difference

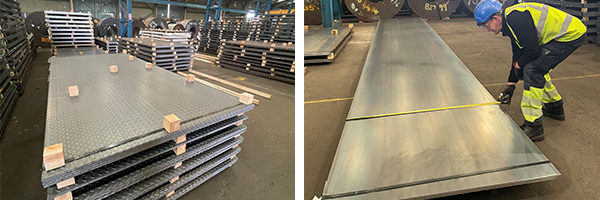

Standard supply no longer matches the reality of modern projects. At ASD, our hot-rolled offering is built around flexibility, not limits. While many suppliers stop at standard grades and dimensions, at ASD we stock a wider range of grades and complement those with in-house de-coiling capability so that the materials we supply fit customers’ needs.

We can de-coil material to precise specifications:

- thickness: 1.6mm to 15mm

- width: up to 2050mm

- length: up to 12000mm.

This level of flexibility allows us to deliver both standard and bespoke hot-rolled products that align perfectly with project requirements, whether that means reducing material waste, meeting specialised design tolerances, or maintaining production continuity on high-volume contracts.

Supply That Grows With You

We’re not just here to deliver steel and move on. We support your project and supply chain teams with sourcing, processing, and materials management that actually works for you:

- sourcing specific grades in a wide range of sizes

- holding parent feed stock for call-off, so materials are ready when needed

- supporting large contracts with a steady and reliable supply

- offering Total Metals Management (TMM) for projects that combine different alloys, value-added processes, and strict timelines under safe conditions.

A Smarter Approach to Supply for Industrial Projects

This isn’t just about technical capability; it’s about how we work with you. If your current supply process is built on compromise, we can help you move to something smarter and more flexible.

By working closely with you from the start, we make sure that every order supports your bigger goals. That might be improving operational efficiency, boosting sustainability performance, or helping you stay competitive in fast-changing markets.

A Future Built on Adaptable Supply Chains

As the UK pushes forward with major infrastructure and energy projects, adaptable steel supply chains will be key to keeping momentum. The ability to source, process, and deliver bespoke materials at scale isn’t just a nice-to-have anymore. It’s essential.

With decades of steel expertise and the ability to deliver bespoke hot-rolled solutions, ASD is helping shape a more flexible, future-ready industry one project at a time.

Ready to move your production forward?

Talk to our team today and discover how our made-to-fit hot rolled plates can boost efficiency and keep your projects running smoothly.