In September 2025, the UK Government released its Defence Industrial Strategy, signalling a decisive shift in how Britain approaches defence procurement and industrial capability. The strategy outlines the government’s intent on making defence an engine for growth, backing UK-based businesses, and developing a resilient UK industrial base. It furthermore prioritises supply chain resilience and securing access to essential materials produced on home soil.

Steel is one of the Industrial Security Priorities

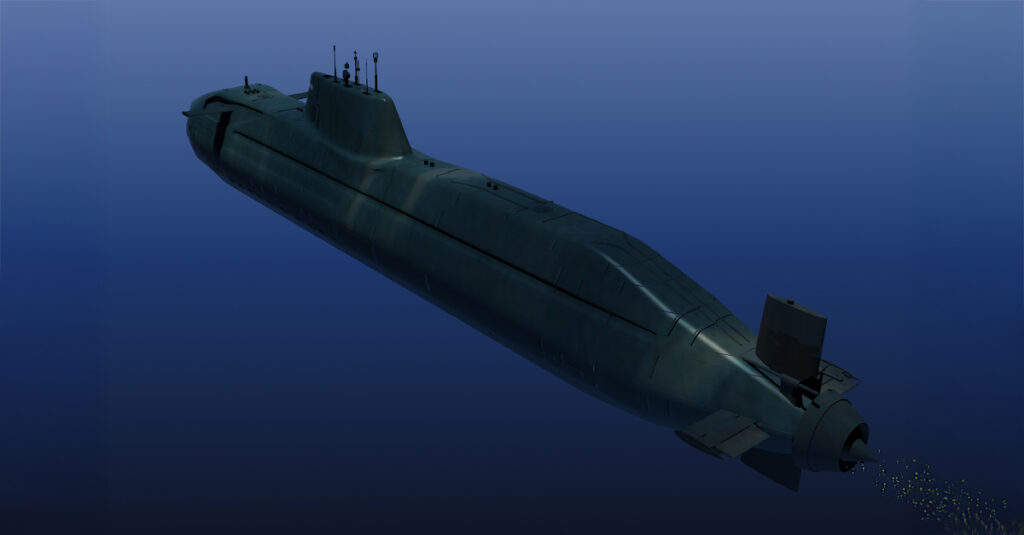

The strategy identifies steel as one of the “industrial security priorities” for supply chains, recognising that when global tensions rise and supply chains tighten, Britain cannot afford to be dependent on international sources for materials that underpin every aspect of defence capability. From warships and submarines to armoured vehicles and advanced weapons systems, steel isn’t just a material, it’s the backbone of defence readiness.

Because behind every ship, vehicle, weapons system, or engineered component is one foundational requirement: the right steel, delivered when it is needed and with full traceability.

The defence capability depends on it, and this is where ASD plays an important role, not just as a supplier, but as a strategic partner supporting the Ministry of Defence (MOD).

Why Supply Chain Resilience Is Now a Defence Requirement

Resilient supply chains aren’t nice-to-have, they’re essential to national security. The strategy’s focus on steel as an industrial security priority acknowledges that every warship, armoured vehicle, weapons system, and piece of defence infrastructure depends on it.

With the MOD now empowered to prioritise UK-based steel suppliers, this approach delivers on multiple fronts: national security, supply chain resilience, and regional economic growth. Steel underpins not just naval vessels and armoured vehicles, but also essential defence infrastructure, from barracks and warehouses to shipyards and logistics hubs.

So what matters when it comes to a truly resilient steel supply chain:

Geopolitical security – Steel sourced from unstable regions or that is subject to export restrictions creates vulnerabilities which Britain cannot afford. Domestic supply means guaranteed access, regardless of global tensions.

Speed and reliability – Defence programmes require materials delivered on time. Delays or long lead times for speciality steel can slow projects and impact operational readiness.

Quality assurance – There is zero margin for error. From Structural and Marine grade steels that must withstand extreme maritime conditions to precision components in weapons systems, consistency and traceability are non-negotiable.

What Makes ASD a Strategic Steel Partner in Defence

When it comes to defence steel, it is not a commodity product and many applications require specialist grades, rigorous controls, and complete traceability from mill to implementation. It includes:

- Marine grade steels designed for structural strength, corrosion resistance, and weldability.

- Armour plates with ballistic protection properties.

- Specialist Stainless steel and Aluminium for extreme environments and weapon systems.

That’s exactly what we deliver at ASD.

So, what should you look for when selecting the right supply chain partner for the defence industry?

Technical Knowledge That Supports Engineering Decisions

Strategic partners are those who have the expertise and the technical knowledge of the application, in addition to the product properties. ASD’s experience with materials used in defence enables technical discussions with engineers, helping ensure the correct grade is chosen from the start. This reduces specification errors, prevents delays, and provides confidence that materials will meet required standards.

Flexible, UK-Based Delivery

It is important to consider a supplier that is able to supply materials on time – a supplier that holds stock in the UK and can deliver instantly. At ASD, we can often deliver in days as we have stock across multiple locations in the UK and can also provide a range of value-added services, enabling processing in-house.

Quality Assurance and Full Traceability

Defence procurement requires comprehensive documentation; from Responsive sourcing, QMS (ie. ISO 9001 and JOSCAR) and Cyber Essentials Plus credentials to full mill certificates including 3.2 Lloyd’s certificates. This isn’t optional: components must be traceable back to their original source in case of investigations into component failures.

ASD’s quality management systems and documentation practices ensure manufacturers receive the full certification packages needed for defence audits and technical compliance.

So, what to look for when selecting the right supply chain partner for the defence industry:

Business Continuity

Defence projects cannot afford supply disruptions. As part of the wider Hierros Añon Group, ASD brings financial stability, a dedicated defence team, UK-based inventory, in-house processing capabilities, and a direct relationship with mills within our group. It’s a level of resilience that many UK steel suppliers simply can’t match. When global supply chains face disruption, having a domestic partner with these resources becomes critical to keeping your projects on track.

Total Metals Management for Defence Innovation

The Defence Industrial Strategy emphasises greater opportunities for SMEs in the defence sector. Smaller companies often lead in innovation but may struggle with a smarter procurement approach.

ASD’s unique service supports these businesses by providing them with our Total Metals Management, offering the following benefits:

- Empowers companies to focus on their operations and internal efficiencies, knowing that all metal requirements are already sourced, scheduled, held in stock, and managed safely on their behalf

- Materials can be ordered and processed to exact specifications and delivered to a location of customer’s choice (Integrated Supply Chain)

- Certainty in quality, documentation, and lead time places our customers in control of their supply chain

- A dedicated point of contact responsible for each project

In doing so, ASD helps SMEs participate more effectively in the defence ecosystem by contributing new ideas, technology, and capability to UK defence programmes.

National Coverage for Regional Defence Hubs

Defence manufacturing is distributed across the UK. From naval yards in Glasgow, Plymouth, and Barrow to aerospace in the Midlands and munitions facilities in Scotland and Wales, all rely on dependable material supply.

ASD’s national footprint helps manufacturers avoid delays linked to distant sourcing, ensuring regional facilities receive the materials they need, quickly and reliably.

If you’re a defence supplier or manufacturer looking for a steel partner that understands the critical nature of your work, let’s talk. Our team is ready to discuss your specific requirements and show you how ASD can help support your projects.