Overview:

The UK’s offshore wind industry is scaling at unprecedented speed, creating a sharp rise in demand for high-performance steel across turbines, foundations, and supporting infrastructure. This article breaks down current and future capacity targets, the essential steel grades required for offshore environments, and how ASD is supporting wind developers and fabricators with certified materials, advanced processing, and UK-wide supply.

Supporting the Infrastructure Behind the UK’s Wind Ambitions

The UK’s offshore energy industry is entering an exciting period of growth. As the country moves toward cleaner power, offshore wind has become central to the nation’s renewable energy plans, creating significant opportunities for the industries that support it. At present, the UK has 16GW of offshore wind capacity already in operation, with a further 10.4GW under Construction and 1.4GW in Pre-Construction. Despite this progress, more than 20GW of additional capacity will need to be delivered by 2030 to meet national targets.

Meeting this demand requires materials and expertise that can deliver performance, reliability, and strength in some of the world’s toughest environments. That’s where steel plays a defining role as it forms the foundations of the offshore energy revolution.

Steel Requirements of the Offshore Wind

The scale of the opportunity ahead is remarkable. Steel is at the heart of offshore wind, making up more than 80% of a turbine and its associated infrastructure, from foundations and towers to nacelles and generators. Over the next three decades, the demand for steel in the offshore wind sector is set to dwarf that of UK defence, highways, rail, and government buildings combined, approaching nearly six times the total of these sectors.

Forecasts indicate that UK windfarms will require, on average, over 1 million tonnes of steel – primarily plate steel – per year between 2026 and 2050, with peak annual demand exceeding 2 million tonnes. To deliver the nation’s 43–50 GW offshore wind target, the UK must increase steel supply by around 20% between 2025 and 2027.

These figures underscore the scale of offshore wind growth and the critical role that UK steel suppliers will play in transforming these ambitious plans into tangible infrastructure.

Meeting the Demands of a High-Risk Industry

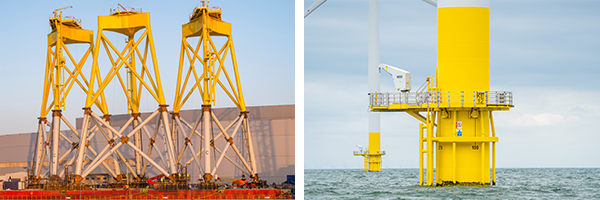

Offshore wind is a high-risk environment, with structures exposed to extreme weather, powerful currents, and corrosive saltwater. Foundations and support structures must perform flawlessly under these conditions, which places exacting demands on the materials used. Steel is essential because it combines strength, durability, and reliability, ensuring that turbines remain stable and safe over decades of operation.

The sector’s evolution toward larger turbines and deeper water installations is creating a rising need for high-performance steel. Structural grades such as S355, S460, and S690 are increasingly relied upon for monopiles, jackets, and transition pieces. Offshore-certified steel that complies with EN 10225 and DNV standards – such as S355J2, S355G, S460N, and higher-strength EH36 or specially weldable steel – are also critical, offering the toughness, fatigue resistance, and weldability necessary to withstand the harsh marine environment. Corrosion-resistant options, including Duplex Stainless Steel and weathering steel like Corten, are sometimes specified for secondary components or exposed structures to enhance durability and reduce maintenance.

These technical requirements highlight that offshore wind is not just about strength; it is about precision and resilience. The right steel enables engineers to design and construct structures that meet both performance expectations and regulatory standards, ensuring the long-term reliability of the UK’s growing offshore wind fleet.

Supporting the Steel Demand of the Energy Sector

At ASD, we supply the steel that makes these structures possible, along with the processing capabilities that make fabrication faster, safer, and more efficient. Here are some of the products we supply to the industry:

- Structural plate and offshore-grade plate (S355 / S460 / S690): High-strength, weldable steel for monopiles, jackets and transition pieces.

- Tubulars and hollow sections: Supplied as kits-of-parts ready for assembly, ideal for jacket bracing and secondary steel components.

- Heavy sections and beams: For lattice structures, access frames and topside platforms.

- Weathering and coated steel: Used where corrosion resistance or visual uniformity is required.

Value-Added Services That Make the Difference

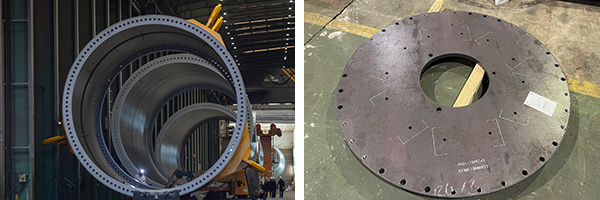

For our customers in the offshore wind, we offer a wide range of value-added services to customise products based on their unique requirements. What’s more? Components can be checked by our team to meet offshore fabrication quality standards and delivered as kits-of-parts. We offer:

- Tube laser cutting and weld prepping – complex geometries and tight tolerances, ready to fit and weld.

- Flat laser, profiling and waterjet cutting – precision profiles and flanges with clean edges and minimal waste.

- Section bending – shaped to exact radius and spec, ensuring seamless assembly.

- Shot blasting and primer painting – corrosion protection and clean surfaces before fabrication.

- 3D measurement and quality assurance – ensuring every component arrives right first time.

Why Partner with ASD

With a strong UK-wide presence, ASD is never far from where the action is. Our network of sites stretches across the country, placing us close to many of the UK’s key offshore wind farms, both those already in operation and those still under construction.

This means we can react quickly when our customers need support, keep projects on schedule, and supply materials for ongoing maintenance just as easily as for new builds. We’ve already supported a number of major offshore wind projects across the UK, providing the steel and expertise needed to bring complex structures to life. Backed by extensive local stock, in-house processing, and technical know-how, we help manufacturers cut lead times, reduce rework, and deliver high-quality steel structures from the first prototype right through to full production.

As the UK pushes ahead with its offshore energy ambitions, we are proud to play our part in supporting a cleaner, stronger, and more resilient energy future.

Ready to Support your Next Offshore Wind Project?

Let’s discuss how ASD can help you meet demanding offshore wind specifications while keeping production efficient and on schedule.

References: