Today, the world uses around 58 million tonnes of Stainless Steel every year – nearly double the amount used just a decade ago. And demand continues to rise, with a projected annual growth rate of 5%. One of the biggest reasons behind Stainless Steel’s popularity is its sustainability – it’s fully recyclable, (approx. 95% of it is recycled once it reaches end of life) with scrap material being particularly valuable to producers.

At the heart of Stainless Steel’s appeal is its corrosion resistance, made possible by a thin, protective oxide layer on the surface – primarily formed by chromium. Unlike mild steel, Stainless Steel is better equipped to handle extreme temperatures, harsh environments, and demanding applications with minimal maintenance. Its attractive finish, combined with its hardness and durability, make it a material of choice across industries.

Even more impressive is that this oxide layer is self-healing – meaning that even if scratched or damaged, it can, in the right environment, reform to keep protecting the steel underneath.

Stainless Steel also performs exceptionally well in cryogenic conditions, especially the austenitic type, which stays strong and ductile in extreme cold – a key reason it’s used in industries like cryogenics and deep-sea applications.

If you’re curious to learn more about Stainless Steel, read on to discover the different types and grades of Stainless Steel and gain insights into what would work best on your upcoming projects.

Stainless Steel Types

There are several types of Stainless Steel, each with distinct performance benefits:

- Austenitic

- Ferritic

- Martensitic

- Duplex

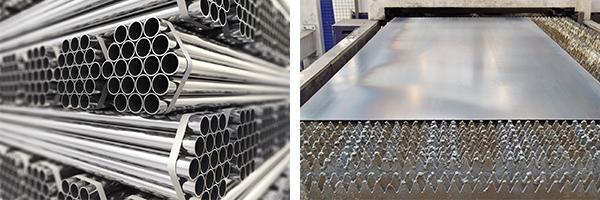

At ASD, we stock a wide range of Stainless Steel grades and types to suit diverse applications.

Grades of Stainless Steel

There are many Stainless Steel grades, each designed with specific properties to suit different applications. The most commonly used grades fall into the austenitic family, with Grade 304/304L and Grade 316/316L being the most popular. Both offer excellent corrosion resistance and versatility.

At ASD, we stock:

- 304/304L and 316/316L: Widely used austenitic grades. We supply flat, long, and tubular products in both. Both grades can be supplied with dual certification.

- 321: An austenitic grade with similar properties to 304/304L but with improved thermal stability. However, it offers lower corrosion resistance in chloride environments compared to 316/316L. Available in cold rolled, hot rolled, and quarto formats.

- 4003 (1.4003): A ferritic grade. We supply selected flat and tubular products in this grade.

- Duplex: We supply flat products in 2205 / LDX2101 / 2507 grades.

Each grade serves a distinct purpose across industries – from food processing and architecture to marine engineering and chemical processing.

Grade 304/304L vs Grade 316/316L Stainless Steel: What Sets These Materials Apart?

Grade 304/304L and Grade 316/316L Stainless Steels are both widely used across a range of industries – but their subtle differences in composition can make a significant impact on long-term performance and suitability for specific environments.

Grade 304/304L is the most commonly used Stainless Steel, known for its excellent corrosion resistance in standard atmospheric conditions. It’s ideal for general manufacturing and environments where exposure to salt or aggressive chemicals is limited. Its affordability and versatility make it a go-to material for general-purpose applications.

Grade 316/316L, however, includes the same base elements but with added molybdenum, a key component that improves its resistance to harsh environments. This makes it particularly valuable in marine environments, coastal infrastructure, chemical processing facilities, and medical-grade applications where durability under extreme or corrosive conditions is essential. It also excels in high-temperature environments and is often used in high-end industrial applications.

Ultimately, Grade 316/316L’s enhanced resistance and reliability under harsh conditions justify its higher cost in critical applications. Grade 304/304L remains a practical, cost-effective option for less-demanding settings. Now, let’s dive into specific applications of each of these across sectors.

Applications of 304/304L and 316/316L Stainless Steel Across Sectors

Both 304/304L and 316/316L Stainless Steels are widely used across industries, with their applications shaped by the specific performance requirements of each sector.

Grade 304/304L Stainless Steel is prized for its versatility, corrosion resistance, and ease of fabrication. It’s the go-to choice for industries where Stainless Steel needs to withstand daily wear and tear but isn’t constantly exposed to harsh or highly corrosive environments.

- In the food and beverage industry, it’s used to produce food-grade equipment like kitchen sinks, countertops, and processing machinery due to its resistance to food acids and its ease of cleaning.

- The construction and architecture sector relies on it for architectural panels, cladding and façades, doors, windows, roofing materials, handrail and balustrade systems, and interior design elements like lifts, escalators, flooring, and mezzanines, thanks to its aesthetic appeal and weather resistance.

- In automotive and aerospace, 304/304L is used for exhaust systems, trim, engine components, and structural parts where strength, ease of fabrication, and moderate corrosion resistance are needed.

- The medical and pharmaceutical industry uses it for surgical instruments, medical equipment, laboratory furniture, and storage solutions because it’s hygienic, non-reactive, and easy to sterilize.

- For household goods, it forms the backbone of appliances like kitchen sinks, cookware, dishwashers, and household appliances.

- In industrial and general manufacturing, it’s a staple for storage tanks, pipes, machinery components, and industrial work surfaces exposed to mild corrosion environments.

Grade 316/316L Stainless Steel, on the other hand, is tailored to more demanding conditions – especially those involving chlorides, chemicals, or marine exposure.

- The marine and coastal industries use it for boat fittings, marine hardware, seawater piping, offshore platforms, and rig components, where saltwater corrosion is a constant challenge.

- In chemical and petrochemical processing, it’s essential for reactors, storage tanks, pipelines, heat exchangers, and other equipment that comes into contact with aggressive chemicals.

- The pharmaceutical and biotech sectors prefer 316/316L for pharmaceutical processing equipment, clean room systems, tanks, and laboratory equipment due to its resilience against chemical cleaners and sanitisers.

- Even within the food and beverage sector, Grade 316/316L is selected for high-end food processing machinery, brewing equipment, dairy equipment, and marine-based food processing units where equipment is exposed to chlorides and salt water.

- The oil and gas industry depends on it for offshore oil rigs, pipeline systems, storage tanks, and drilling equipment in environments with exposure to harsh chemicals and salt water.

While both grades offer strength, durability, and corrosion resistance, the choice between 304/304L and 316/316L ultimately depends on the severity of the operating environment and the nature of the application.

Want to find the right Stainless Steel for your application?

Get in touch with our team for tailored advice, and make sure to follow along, as our next article will explore other specialist grades we supply, including 321, 4003, and Duplex Stainless Steels.

Related articles: