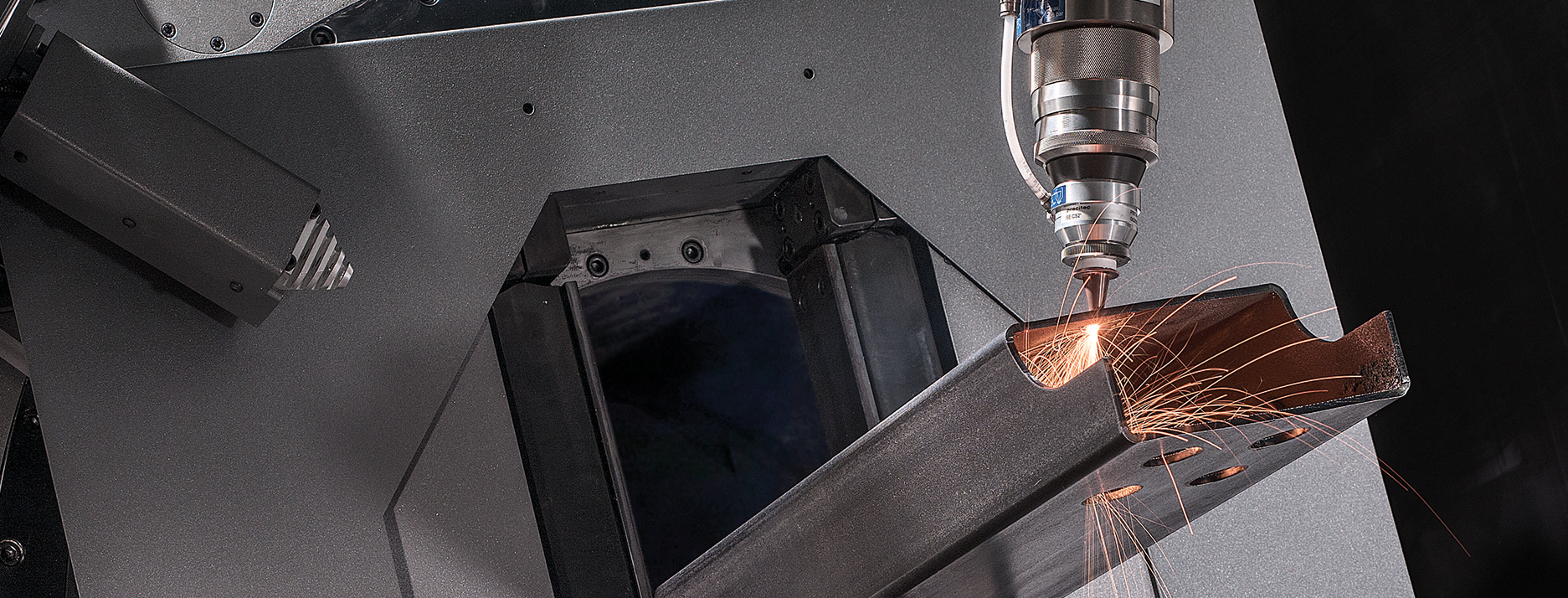

THE POWER OF 3D TUBE LASER CUTTING

ASD’s laser processing centre of excellence boasts an impressive portfolio of state-of-the-art 3D laser cutting machines. Extensive processing capabilities in combination with our talented CAD team, allow us to offer the complete in-house solutions no matter how large, small or complex your cutting requirements.

When it comes to fabrication and assembly of mechanical sections, 3D cutting not only brings significant processing and economic benefits but also allows us to thrill our customers by delivering sustainable innovative solutions.

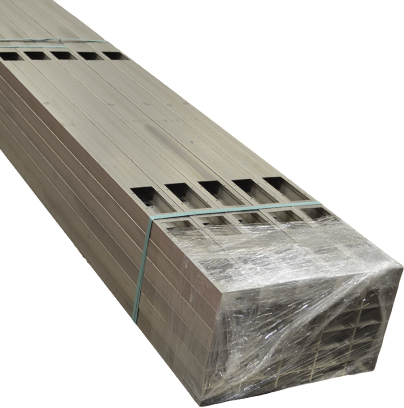

LT14 Jumbo Laser Capabilities

- Processing Hollow sections and structural profiles, including:

-

- Round tube: up to Ø355mm

- Square tube: up to 250x250mm

- Rectangular tube: up to 300x200mm

- Channel: up to 300x100mm

- Equal angle: up to 200x200mm

- Unequal angle: up to 200x150mm

- Universal columns: up to 254x254mm

- Universal beams: up to 305x165mm

- Bar weight: up to 100kg/m

- Infeed/outfeed: 15.5m

- Standard Materials: Steel and aluminium

- Laser cut up to 20mm thick mild steel

- Weld prep 16mm thick mild steel material up to 45 degrees

Customer Benefits

- Provision of kit of parts ready for assembly

- Capacity to process large volumes of project work with close tolerances and complex geometries.

- Ability to service contractual work and repetitive requirements

- Shorter lead times and improved productivity (up to 80% gain over conventional methods)

- Supports creative, complex designs and innovative fabrication solutions

- Reduced downstream costs due to tighter fabrication tolerances

- High-quality, precision-cut components for faster, more accurate assembly

LT8 & LT722D Laser Capabilities

- Round tube: 12mm – 220mm

- Square tube: Up to 200 x 200mm

- Tube loader length: 12.5m

- Unloader length: 8.5m

- Bar weight: Max 35kg/m

- Source laser power: 3500W

- Digital CNC: Siemens 840D Solution Line

- Standard materials: Steel, Stainless Steel, Aluminium, Others on request

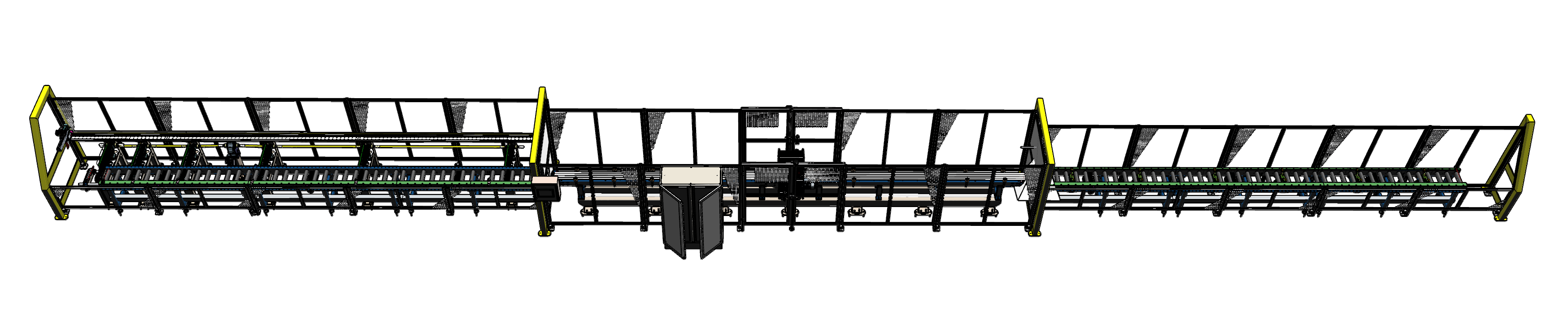

Laser-Array Automated Inspection Line

To ensure dimensional accuracy on critical laser cut components part of our set up includes a bespoke laser-array automated inspection line. This non-contact laser measurement system allows us to offer our customers heightened quality assurance by providing measurement capabilities for length, section dimensions, straightness, twist and cut features – for sections up to 200 x 100 x 9m.

Ready to find out more?

Drop us a line today for a quote!