A SMARTER ALTERNATIVE TO INSERTS AND WELD NUTS FOR THIN-WALLED MATERIALS

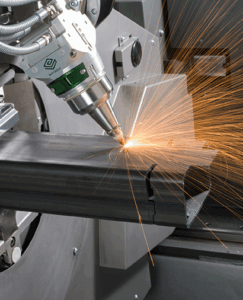

At ASD, we offer Flow Drilling (also known as friction drilling or thermal drilling) as a complementary service to our tube laser parts.

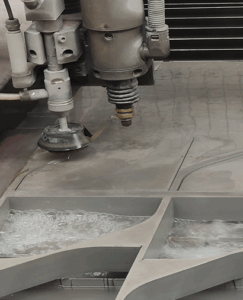

Using high rotational speed and pressure, Flow Drill creates a clean, accurate hole without material loss. Instead, the displaced material forms a collar or sleeve around the hole, increasing the material thickness by up to three times. This eliminates the need for additional fasteners like rivet nuts or inserts.

What This Means for You:

- Stronger threads in thin materials – ideal for material thicknesses up to 3mm

- Replaces river nuts, weld nuts, or insert nuts

- Waste-free process – no chips or offcuts

- High process reliability – consistent, repeatable results

- Fast and efficient – integrated with our in-house laser processing for streamlined production

Finishing Options

We offer both collar and plane surface finishes, depending on your project requirements.

Whether you're working in automotive, construction, renewables, or general fabrication Flow Drilling solution gives you a stronger, cleaner, and more cost-effective way to create threaded connections in thin-walled materials.

Ready to find out more?

Drop us a line today for a quote!

Other Value-Added Services