SAVE TIME AND REDUCE COSTS IN STEEL PROCESSING

ASD’s nationwide portfolio of state-of-the-art drilling lines is transforming how we support customers – cutting costs and saving time in your subsequent processing stages.

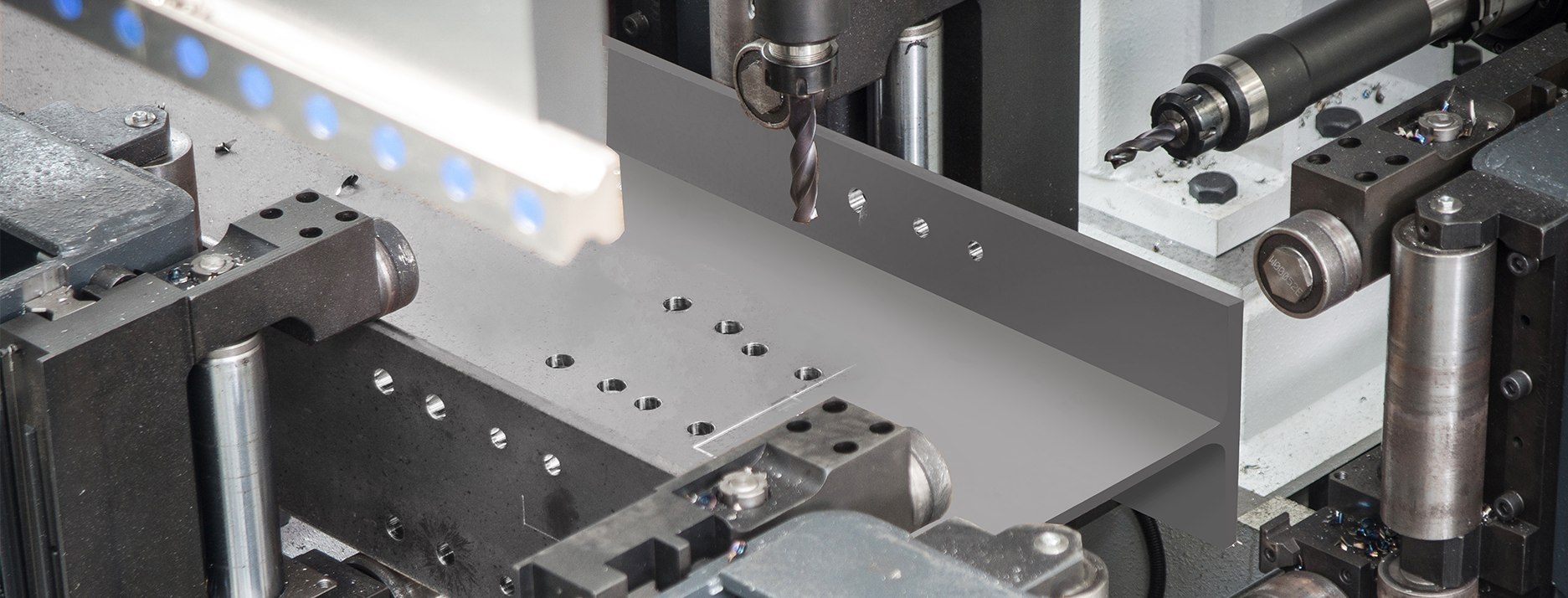

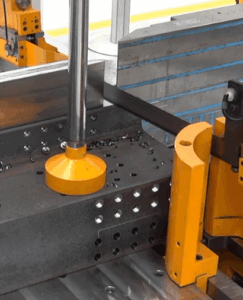

What sets our high-speed machines apart? They can simultaneously process flanges and webs, drastically cutting labour hours. With three drill heads and automatic tool changers (up to 8 tools each), we deliver high productivity and precision in a single pass.

And if your next project stage involves applying shear studs or fittings, we can also pre-mark exact locations, saving you valuable time during assembly.

From faster turnarounds to cost-efficient, ready-to-use materials, can help customers streamline operations and boost performance.

Capabilities:

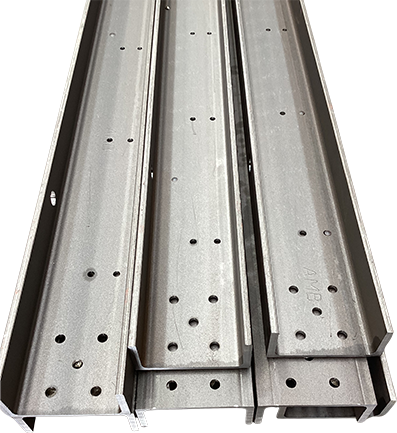

- Processing: Beams, Channels, Columns, T Sections, Square Tubes, Flat Steel, Angles

- Automatically processing materials ranging in lengths from 2800mm up to 20200mm, with a manual feed capacity of a minimum of 45mm to a maximum of 20200mm

- Part marking / stamping most products with bespoke identifying marks or cast numbers

- High-quality holes in a wide range of diameters

- Ability to countersink, tap and thread holes

- Precision milling

Ready to find out more?

Drop us a line today for a quote!