Introduction

This document provides guidance to structural engineers on the fire design output in Westok’s Cellbeam 10.4 software, and explains the simple process of presenting this information on the engineer’s drawings and specification documents. Definitions of the key terms are provided at the end of the document.

The approach aligns with the methodology set out in the recently published ASFP document Fire protection for structural steel in buildings, 6th Edition (Yellow Book).

Overview of Cellbeam 10.4 Fire Design Methodology

Westok’s Cellbeam software carries out a fire analysis using an ‘unprotected’ model. This calculates the incremental rise in temperature of the Westok beam, specifically the elements of the cross section (e.g. bottom flange, top flange, web) of an unprotected beam exposed to the standard cellulosic fire curve, as defined in BS EN 1991-1-2.

In 5 second time increments the temperature of each element is increased, in accordance with BS EN 1994-1-2, with the temperature change of the flanges and web being a function of their respective section factors.

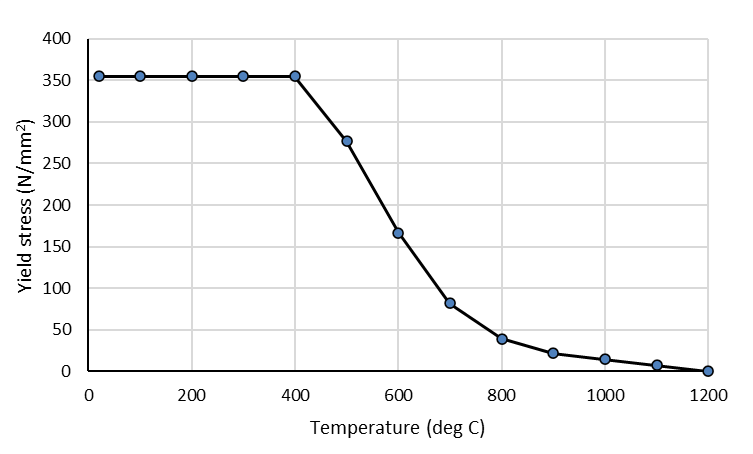

The increased temperature results in a reduction in the strength and stiffness of each element of the cross section (see Fig 1) and a structural fire design is then carried out, in accordance with SCI publication RT1356, based on modified section properties.

As the temperature rises and strength continues to fall, failure eventually occurs, and the analysis stops. The temperature of the element which has failed is known as the ‘critical temperature’. The relevant pieces of information reported by Cellbeam are:

- The critical temperature,

- The failing element (bottom flange, or web),

- The section factors for these elements.

ASFP Yellow Book 6th Edition

A methodology for the fire protection of cellular beams is given in Annex C of 6th Edition of the ASFP Yellow Book, published in January 2025. The purpose of intumescent paint is to prevent the cross section from reaching the critical temperature until the fire resistance period has elapsed. The fire resistance period is generally specified by the architect.

The process to establish a thickness of reactive fire protection on three and four-sided members is given in Figures C.4 and C.5 respectively. It should be noted that the specification of a product and application thickness can only be carried out by an organisation with access to test-based EMTA data and web post modification factors – this may be the paint manufacturer, applicator, or a specialist fire protection consultancy. It is the engineer’s responsibility only to report the appropriate data. An example of the specification process is given below.

Example of the derivation of a beam-specific intumescent product / thickness using output from Cellbeam 10.4

Step 1: Structural Engineer’s responsibility - assemble structural design data numbered below

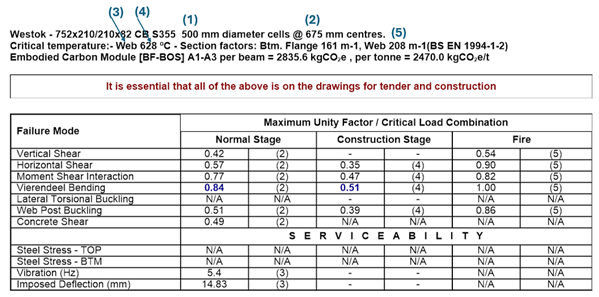

This step is illustrated with reference to a typical Cellbeam summary report (see Fig.2 ).

Fig 2: Cellbeam 10.4 Summary Output Report

A. Clarify the web post width. In the above example the cell diameter (1) is 500 mm and the spacing (2) is 675 mm, so the web post width is 175mm.

B. Note the failure element. In the ‘Fire’ unity factor column the failure mode is shown to be Vierendeel bending (UF = 1.0). Reference is therefore made to the next highest utilisation, which is horizontal shear. The failure is therefore in the web element (3).

C. Note the critical temperature. The critical temperature is given as 628 degrees Celsius (4).

D. Determine the section factor associated with the critical element. The Cellbeam report provides section factors for the web and the lower flange. In the above example, since failure is in the web, the relevant section factor is 208 m-1 (5).

E. Clarify the fire resistance period. The fire resistance period will normally be specified by the Architect and is likely to be 30, 60, 90 or 120 minutes.

F. Note exposure type: Since the beam supports a composite metal deck the exposure condition is three-sided. See the ASFP Yellow book for further guidance.

It is structural engineer’s responsibility to confirm these important pieces of information. It is recommended that this data is included in the notes or tabulated on the drawings, where the other details of the cellular beams are set-out. See example table is given below.

| Ref | Size | Top Tee | Bottom tee | Precamber (mm) | Cells (dia@ctrs) | Failure Element | Critical Temp (C) | Section Factor (m-1) |

| WB1 | 752x210/210x82CB | 533x210x82UB | 533x210x82UB | 30 | 500@675 | Web | 628 | 208 |

Table 1: Example tabulated fire data

Step 2: Paint specifier’s responsibility - specify product and dry film thickness (DFT)

Using the information provided by the structural engineer in step 1, it is the paint specifier’s responsibility to specify the required thickness of paint protection using the web modification factor and the EMTA product data for their chosen paint product. For three-sided exposure the specifier will follow Figure C.4 of the ASFP Yellow Book 6th Edition.

- Select a product: Many factors outside the scope of this guidance note may have a bearing on product selection, e.g. factory or site application, suitability for specified fire period, etc… this will be discussed in a guidance note to follow.

- (For web failure) Determine the web modification factor: The web modification factor is derived from tests and is a function of the web post width, product, and fire resistance period.

- (For web failure) Derive the equivalent solid web temperature: This is simply the web critical temperature divided by the web modification factor.

- Determine the Dry Film Thickness (DFT): The required DFT is derived from an EMTA table based on the paint manufacturer’s tests and for a web failure is a function of the equivalent solid web temperature, selected product, section factor, and fire resistance period.

The output from step 2 (paint specifier’s responsibility) is:

- Recommended product

- Associated DFT

ASD Westok’s Technical Advisory Service

Westok offers a free design service, and our engineers have considerable experience with the optimised design of steel framed structures. We deliver dozens of CPDs each years across a variety of topics. To get in touch with our engineers, please email us on westok.design@asd.ltd.

To download our free design software, please visit

Definitions of key terms

- Web post width: The narrowest width of solid web between two adjacent cells.

- Critical temperature: The temperature at which failure of the structural steel section is expected to occur. In Cellbeam, flange failure modes comprise moment / shear interaction and lateral torsional buckling, web failure modes comprise vertical shear, horizontal shear, web post bending and web post buckling. The Vierendeel failure mode may comprise either element and in this case the failure mode with the next highest utilisation determines the failure element.

- Section factor: The ratio of the heated surface area (A) to the volume (V) of the member. Members with low section factors (A/V) will heat up more slowly.

- Fire resistance period: The fire resistance period of each loaded steel section is the duration of the test until the specimen is no longer able to support the test load.

- Web modification factor: A test-based factor to convert a cellular beam critical web temperature derived from the structural model to a product specific equivalent solid web temperature at failure. Web modification factors are currently confidential.

- Elemental multi temperature assessment (EMTA). In order to use the principles of RT1356 to determine a critical temperature it is necessary for the testing and assessment of solid beams to take the form of an EMTA that considers the assessment of the webs and lower flange separately. Product data derived from EMTA assessment for cellular beams is currently confidential.