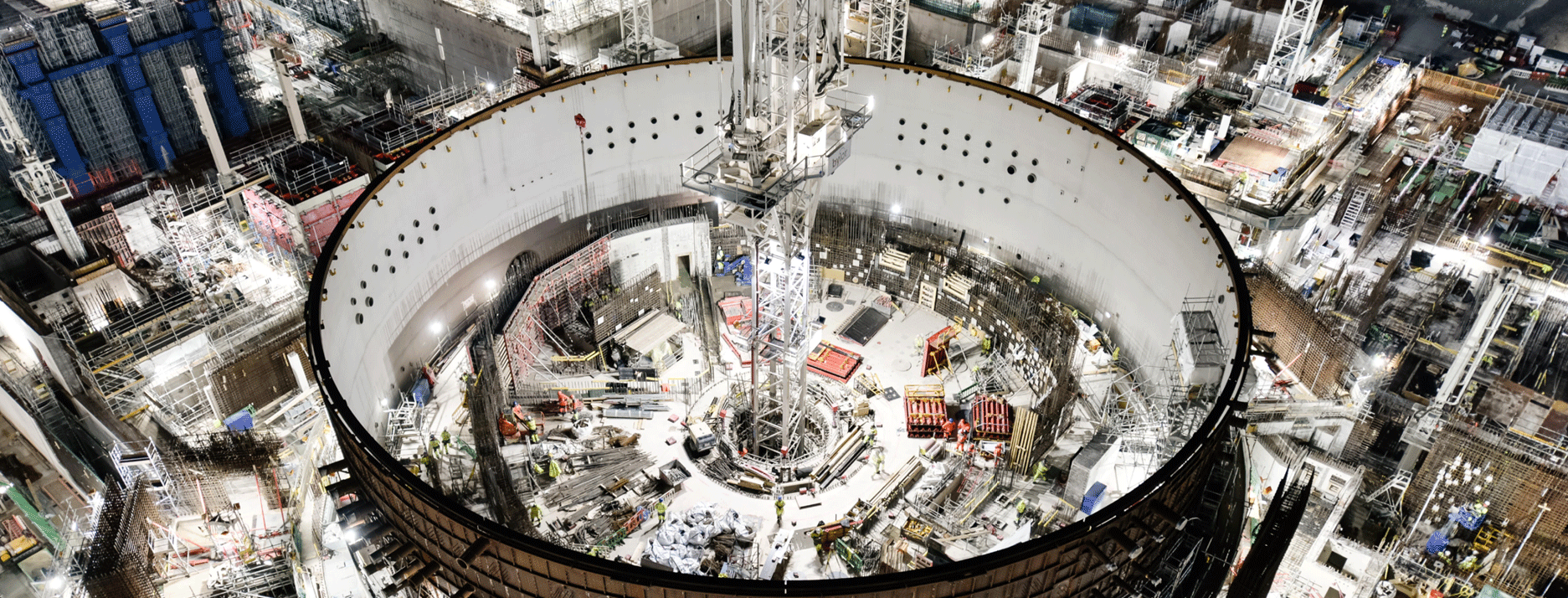

Hinkley point C Power Station

At ASD we are one of the UK’s leading stockholders and processing suppliers of multi metals for construction and high integrity sectors such as nuclear.

The company was awarded a multi-million Pound contract by BYLOR to produce embedment sleeves for Hinkley Point C.

This newly awarded contract will see ASD supply processed and coated embedment sleeves to Tier 1 Contractor BYLOR – a Laing O’Rourke and Bouygues TP joint venture. Throughout this contract we will be assisted by two local South West businesses on the coating of the embedment sleeves.

Peter Whiting, CEO of ASD:“BYLOR’s decision to select ASD as their supplier is a huge endorsement for our capabilities and management expertise. We are extremely excited to be part of such an important national project.”

OUR EXPERTISE & CAPABILITIES

Part of the global Hierros Anon Group, we are certified with Fit 4 Nuclear status (F4N), which is a testament to our commitment to continuously improve operational standards in line with nuclear requirements.

Our nationwide operation facilities, allow us to actively supports UK nuclear activities, including decommissioning, new-build and power generation requirements.

ASD has actively supported the reactor maintenance programme at Hinkley Point B for almost 10 years and we are also a key partner in the manufacture of 3m³ waste containers for the UK’s largest waste retrievals programme.

Our business support services include the stock holding of over 50,000 tonnes of carbon, stainless and aluminium materials, extensive tubular and flat lasering, plasma and waterjet cutting capabilities and a press braking and pipe bending service.

Additional services include quality/Inspection test planning, destructive/non-destructive testing management, and a robust supply chain service which we carefully manage to protect our customers from counterfeit, fraudulent and suspect items.

ASD’s dedicated team of experts are always on hand to ensure that customers benefit from both the firm’s nuclear expertise and our nuclear safety culture. Our team can also support you on project management activities having extensive experience on large projects within such high integrity sectors.

For Hinkley point C, ASD’s products are processed at our Leeds and Dudley facilities before being coated at its South West contractors and shipped to the HPC site for assembly by BYLOR.

Steve Tyrer, Business Development Manager – Nuclear: “The contact with BYLOR at HPC has enabled ASD to invest in a further saw line with operator, a business administrator and a project engineer who are now all dedicated and committed to this project.

“We started working with Somerset Chamber’s Hinkley Supply Chain back in 2012 and have been supported by the team as and when opportunities arise.

We took a seat at the Somerset Energy Innovation centre business hub in Bridgwater where we were able to improve our networking with both the Chamber and SWMAS. This led us to a BYLOR supply chain event, where we started our BYLOR journey, which led to the embedment sleeve contract award.”

The supply team placed ASD onto their supply map where Tier 1 and 2 contractors could see our business capabilities and value proposition. Regular discussions with the team shaped our strategy for engagement with main contractors and this was vital to us.”

To learn more about ASD’s aspects of Nuclear safety click below:

Part II: Nuclear Safety – CFSI Management

Part III: Nuclear Safety – Cross Contamination Controls

Part IV: Nuclear Safety – Testing of Metals